Megawatt solar array installation at the Depue Warehouse Co. rice processing facility at Willows, California, the U.S.A.

BY Steven G. Hummel, Mesa Scharf, J. Michael Fife

Challenges

Solar power plants of tomorrow must be considered by utilities as part of their overall generation asset base. There are many challenges the solar industry must address to achieve that goal:

● Integration: Bi-directional communication and control protocols must be developed to integrate with existing systems. This is essential both for basic systems management and reporting as well as to provide important grid-support functionality such as Low-Voltage Ride Through (LVRT--the ability to deal with temporary voltage changes due to faults or load changes on the grid), VAR (reactive power) support and ancillary services such as voltage regulation and possible future support for intentional islanding (when a utility creates localized power “Islands” in order to deliver power to critical customers in the event of a utility network failure).

● Cost: Improvement is needed in the overall energy economics (kilowatt-hours generated per dollar spent) of the solar plant. Improving the Levelized Cost of Energy (LCOE’s measure of the total lifecycle costs associated with a PV system divided by the expected lifetime energy output, adjusted by factors such as time value of money, etc.) involves not only initial equipment cost reductions, but improved reliability, energy harvest, installability, and serviceability as well as improved models for predicting those factors and their associated costs in spite of the complex issues of system complexity and environmental exposure.

● Monitoring: Supporting utility-scale solar installations will require improved tools for monitoring the output of the entire system and providing a single source for performance data that takes into account increased system complexity and the numerous options available.

● Stability: Reducing the instability of PV power inputs into the grid due to environmental factors is also essential.

Solutions

In 2008, the US$24 million Solar Energy Grid Integration System (SEGIS) project was commissioned by the U.S. Department of Energy as part of the Solar America Initiative (SAI) to encourage the development of new technology and products to significantly accelerate penetration of solar Photovoltaic (PV) systems into the utility grids of America. The SEGIS project funds critical R&D to ensure solar energy solutions are cost-competitive with conventional forms of electricity. Now in the second phase of the program, five teams across the country are working on various aspects of the project. One team, led by PV Powered, Inc., a Bend, Oregon-based maker of solar power inverters, is charged with developing an integrated solution with the functionality essential for high penetration PV:

● Advanced utility-scale system integration including monitoring and control systems that decrease operations costs, prevent islanding, and enable LVRT and other grid-support functions,

● Improved reliability, efficiency and energy harvest offering better energy economics,

● String and zone monitoring and Balance of System (BoS) optimization, and

● Mitigation of weather-induced transients.

Utility Systems Integration

As PV penetration on the utility grids of America continues to rise, new problems begin to emerge. These problems are generally associated with two key areas:

1. The intermittent nature of the distributed PV resource

2. The conflict between utility needs and existing grid interconnect standards governing distributed resource connection to the utility grid.

Both of the above problem areas are complex and cannot be solved by one entity alone and will not likely be completely solved in the near future. The final solution will only be realized when interconnection standards have been changed to embrace PV as a key energy generation asset for utilities. Additionally, smart grid communications infrastructure will likely be required to fully solve all of these problems at a level that addresses high penetration of PV in the case of highly distributed residential solar generation. As first steps toward this goal, the PV Powered-led SEGIS team is focusing on development in the areas described below.

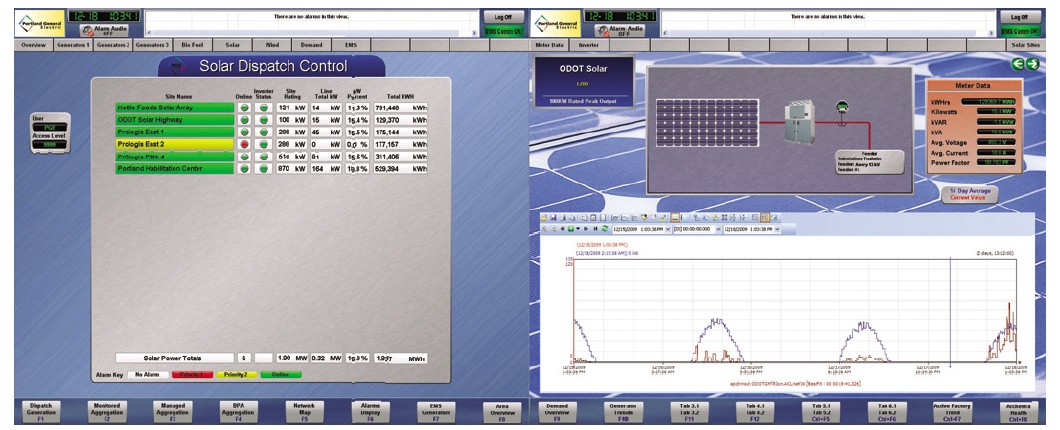

Figure 1. Control screen from Portland General Electric’s GenOnSys Solar Dispatch Center (Source: PV Powered)

Two-way Utility Communications and Control

PV Powered and Portland General Electric (PGE) are working to integrate two-way communications between the solar power plant and PGE’s GenOnSys distributed resource command and control (SCADA) system. This will enable the utility to disconnect their fleet of distributed resources remotely if needed, and receive status and assert control commands as necessary. Figure 1 shows PGE’s GenOnSys Solar Dispatch Control application.

Smart Power Islanding Detection

One of the key points of the IEEE 1547 distributed resource interconnection standard is to ensure that an unintentional power island never occurs for more than a very short period of time (less than two seconds) on a normally utility-connected distributed resource (PV system). This function is typically performed by a sophisticated set of algorithms that provide active control and passive monitoring within an inverter to determine if an unintentional island has been created. A weakness to this approach is that the inverter cannot differentiate between a true utility outage (where anti-islanding is necessary) and a grid disturbance in which grid support from the PV system could assist in utility stability. Current methods can, therefore, cause the inverter to disconnect from the grid when the additional power is needed most. This problem will become increasingly destabilizing as PV power plant grid penetration expands.

The PV Powered SEGIS team is focused on demonstrating a new method for island detection by leveraging synchrophasor measurements taken between the solar power plant and a utility reference. Synchrophasor measurements are derived from two Phasor Measurement Units (PMUs) that take measurements at different locations in a power system, using the same absolute time base. This technique provides an easy method of correlating values from different locations that take different amounts of time to arrive at a common collection point, which in turn will enable the inverter to differentiate between a true unintentional island case and a case where grid support from the PV plant is required. With this foundational block, the industry will have one of the key technology components in place to embrace increasing PV penetration.

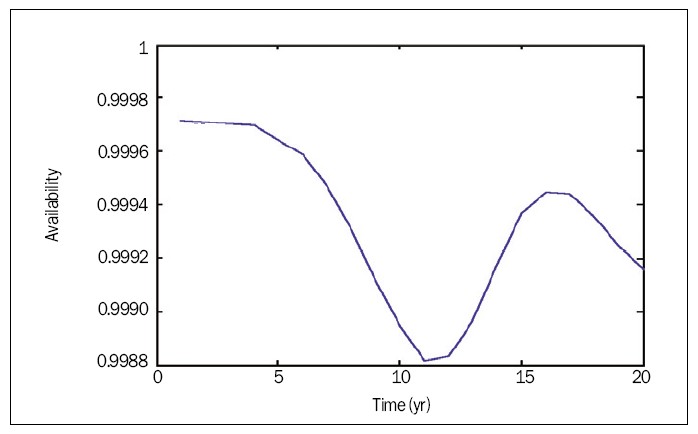

Figure 2. Availability of the example inverter based on downtime due to failure (Source: PV Powered)

Energy Economics

The second major focus area of the SEGIS program is energy economics. To achieve widespread adoption of PV, solar power plants must achieve maximum energy harvest while being reliable, economical, and easy to install and service. This includes three areas of development detailed below.

Reliability

High reliability is a fundamental requirement for PV systems that are expected to provide a positive Return on Investment (ROI). When designing large solar installations, an accurate prediction of the availability of each subsystem is critical to projecting energy harvest and ROI of the installation. Accurate predictions, however, are extremely difficult due to the numerous components and factors involved and because most types of equipment in the solar power industry are relatively new. It is possible, however, to collect reliability data on the different subsystems (power inverters, panels, tracking devices, etc.) and combine them into a system-level analysis. This analysis can then be used to plan preventative maintenance schedules, budget for spare parts, estimate projected downtime, and determine the PV plant’s overall financial viability.

Most large-scale solar power plants include multiple arrays, inverters, and other balance of system components arranged modularly and to some degree in parallel such that single point failures cannot by themselves or through a propagating fault cause immediate shutdown of the entire system. Instead, upon failure of a single subsystem, the plant typically suffers a fractional loss in power output. Once subsystem downtimes and availabilities are known, they can be used to calculate system-level availability, power loss, and energy harvest.

Unlike many other types of power plants (e.g., hydroelectric, nuclear, coal- or gas-fired) which typically reside in a controlled environment like a building, most components of a solar PV power plant are directly exposed to the outside environment. This exposure subjects them to environmental stresses such as temperature fluctuations and extremes, humidity, corrosives, dust, etc. which are influenced by the geographic location of the installation and which must be factored into any reliability analysis. To accurately predict component stresses and associated wear-out mechanisms that solar inverters experience due to natural sun cycles, a complex time-dependent modeling approach is required. Because temperature cycling contributes to device wear-out, simpler constant hazard rate calculations that might apply in other situations are not accurate in this case. PV Powered has created a set of time-dependent prediction tools and analytical methods to predict inverter reliability. Inverter availability can then be calculated as a function of time based on the inverter downtime, as shown in Figure 2. Note that there is a distinct initial reduction in inverter availability corresponding to the mean wear out time of a hypothetical component. The drop occurs during the wear-out period, and the recovery occurs after repairs are made and the worn out parts are renewed.

Energy Harvest

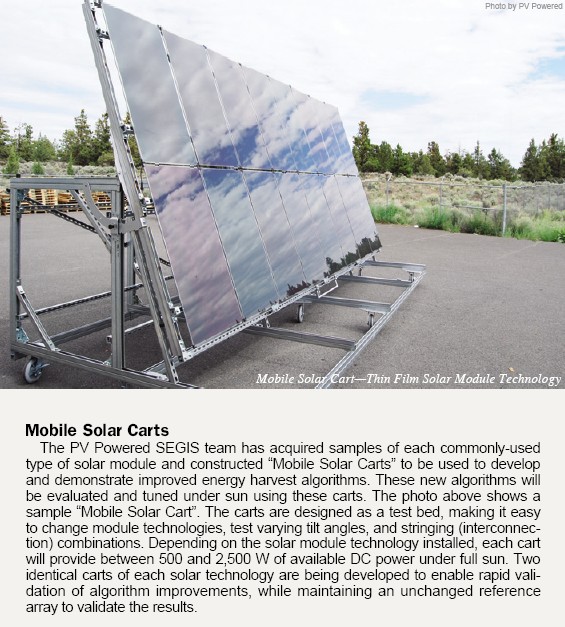

Maximum Power Point Tracking (MPPT--varying the ratio between the voltage and current delivered by a solar array in order to deliver maximum power as the array output changes) is a key function of solar inverters and can affect overall effective solar power plant efficiency by a substantial amount, especially under dynamically changing irradiance conditions. As inverter power conversion efficiency from the arrays nears theoretical maximum, the accuracy and efficacy of the MPPT algorithm emerges as one of the few remaining high value opportunities to increase total energy harvest. The PV Powered SEGIS team is developing a dynamic test plan for quantifying MPPT efficiency and a new MPPT algorithm that provides highly accurate tracking efficiency over static and dynamic irradiance conditions for a wide variety of PV technologies. Systems that will be tested range from high fill-factor technology like concentrated solar or monocrystalline silicon to low fill-factor thin film technologies like Copper Indium Gallium arsenide (CIGS) and Cadmium Telluride (CdTe).

Improved Power Plant Balance of System Components

Along with improving component reliability and energy harvest, for utility-scale installations, it is essential to monitor not just the performance of individual components, but of each system as a whole. A “smart combiner” device, added to the system between the arrays and the inverter, provides string level current monitoring, as well as monitoring for groups of strings in the case of thin-film module technologies where string count is high and string current is low. Through the SEGIS program a more tightly integrated BoS architecture is being developed that can enable better system management and increase overall energy production at an acceptable cost. These advances will lead to less downtime and more predictable operation, improving the overall economic equation for solar power plants.

Mitigating Irradiance Transients

Unlike other forms of power generation, the inputs to a solar power system are inherently variable due to weather and fluctuations in cloud cover and, therefore, leading to instability of the power entering the grid. This is one of the main barriers to high-penetration PV. Use of irradiance forecasting can mitigate the impacts of irradiance transients.

There are two levels of irradiance forecasting being explored as part of the SEGIS research:

● Utility level--allows more optimal integration into utility real-time dispatch processes.

● Inverter level--uses intelligence on cloud position, movement, and transparency to “soften” transients that the utility sees.

Through industry partnerships such as the SEGIS program, the technologies and standards are being developed that will enable the PV industry to solve the economic and technical issues and enable solar power to fulfill its promise as a critical renewable energy component on the national grid.

Dr. Steven G. Hummel is Vice President of Engineering for PV Powered, Inc. (http://www.pvpowered.com/) With 30 years of R&D, innovation, and technology executive experience, Dr. Hummel is the author/co-author of more than 85 technical papers, has 11 patents filed or granted, and is a Senior member of the IEEE.

Mesa Scharf is Strategic Program Manager for PV Powered, where he is responsible for R&D and SEGIS (Solar Energy Grid Integration System) programs.

Dr. J. Michael Fife is Director of Reliability for PV Powered. His past experiences include managing engineer at Exponent, Inc. (formerly Failure Analysis Associates), and aerospace research engineering roles at the Air Force Research Laboratory Electric Propulsion Group and NASA Dryden Flight Research Center.

For more information, please send your e-mails to pved@infothe.com.

ⓒ www.interpv.net All rights reserved |