To help our readers understand you better, please give us a brief account on how the company entered the solar photovoltaic business. To help our readers understand you better, please give us a brief account on how the company entered the solar photovoltaic business.

Manz Automation was originally a company for automation systems for different industries. Already one year after our foundation in 1987, we developed the first automation system for processing crystalline solar cells in a pilot manufacturing project. Back then we started to develop into what we are today--an integrated solution equipment manufacturer. 2002 marked the second milestone in the PV sector: Manz implemented the first system for a fully-automated manufacturing line for crystalline solar cells. At the same time, the first fully-automated quality testing and sorting system for crystalline solar cells was developed by Manz. Already in 2005, Manz Automation entered into the thin-film market by providing equipment for the mechanical scribing of solar modules. Due to the acquisition of Manz Automation Slovakia and Intech (Taiwan), Manz gained additional technological expertise and manufacturing capacity in 2008. Today, we are one of the leading equipment manufacturers for the PV industry in the world. The strategic alliance agreement with Wrth Solar for exclusive rights of use to its CIGS production technology is a logical extension of our strategy. By doing so, we are currently the only company who can offer an integrated, fully productive production line for CIGS solar modules that can be operated cost efficiently (Manz CIGSfab).

Could you tell us some of the competitive edges that differentiate you from your competitors in the solar market?

Basically, we develop innovative technologies for the solar industry that help to ensure and expand our international market position. Due to the acquisition of Intech Co., Ltd., Taiwan, we improved our footprint in Asia considerably and are able to participate strongly in the Asian market with the highest expected growth rates in the PV industry. Being in Asia offers us both cost advantages compared to competitors with production facilities limited to Germany as well as technological leadership against local competitors. Applying Manz technology enables manufacturers to effectively counteract the ever-increasing cost pressure. All in all, our massive expenditure in R&D puts us in a very comfortable competitive position. Manz is in a leading market position for a wide range of solar equipment, as we deliver systems with highest throughput rates and at the same time lowest breakage rates. In addition, our R&D focus is also on increasing the efficiency of solar cells and thereby driving down the costs for solar cell manufacturers. In 2010, we were able to increase our technological edge in the field of CIGS thin-film modules by the alliance with Wrth Solar. This enables us exclusive access to the results and experience of more than ten years of R&D regarding CIGS modules with an industry leading conversion efficiency level.

How do you evaluate your performance last year and how much growth do you expect for this year?

2010 was dominated by a substantial economic recovery which had positive effects on all our company’s operations. For this reason, our order situation in 2010 has continued to improve, and our new products such as the SpeedPicker and OneStep Selective Emitter technologies have been particularly well received. Our existing capacities are already well utilized and steadily approach towards a pre-crisis level. Even though the final figures aren’t available yet, we firmly believe that we have closed out the 2010 fiscal year with a total amount of revenues between 170 and 175 million euros. At the same time, we are confident that we have reached our goal of a balanced EBIT for 2010. This means we will in all likelihood be in line with our forecast made in our 9M 2010 financial report.

In addition, we are looking towards a bright future. That is why we are anticipating double-digit growth in the current business year, driven strongly by the dynamic development in the Asian markets, where we are already generating almost 75% of our revenues--and this share is rising.

In the solar market, where did you put your focus last year in terms of both business growth and technology development? In the solar market, where did you put your focus last year in terms of both business growth and technology development?

We focused on business growth and further technology development. From our point of view, only with highly innovative technologies we will be able to acquire new orders and help our customers to reduce their costs--and thus be competitive. High R&D expenditures are crucial: Currently more than 75% of the order backlog stems from recent developments.

We signed a strategic alliance agreement with Wrth Solar GmbH & Co. KG in 2010, initially for a ten-year period. This gives us exclusive rights of use to its CIGS production technology and means that we are now the only provider who can currently offer an integrated, fully productive production line for CIGS solar modules that can be operated cost efficiently. With a record level for lab cells of 20.1% in efficiency, CIGS is the world’s most effective thin-film technology. The cooperation is a key milestone in securing innovation leadership for thin-film technology and we aim to use the alliance to become the market leader as a provider of CIGS production lines (Manz CIGSfab). As a result, we offer thin-film technology a new impetus and get access to a significant market potential. Wrth Solar will closely work with us during the ramp-up of the new CIGSfab production lines and will put its focus on trading thin-film solar modules. In total, the revenue potential for one CIGSfab with a capacity of 120 MW per year is around 150 million. The fast growing solar market will offer the potential to us to sell multiple lines per year. We are forecasting a significant growth in sales and earnings from this cooperation starting by 2011.

Producing high-efficiency solar cells in a cost-effective way has always been the issue for the solar industry. How is Manz Automation tackling it? Producing high-efficiency solar cells in a cost-effective way has always been the issue for the solar industry. How is Manz Automation tackling it?

Two factors, in particular, play a significant role in the cost effectiveness of solar cells compared to traditional energy sources--low costs and, at the same time, a high efficiency level of the solar cells. With our superior, highly efficient range of products, we fulfilled one of our main objectives: The retaining of our position as the market’s technological leader after the financial crises. We will continue to further optimize processes, increase the speed of our machines, and improve the efficiency of solar cells and modules. Our goal of cutting manufacturing costs for our clients while at the same time improving performance will still apply in the future. Particularly in light of declining feed-in tariffs, solar manufacturers must significantly reduce costs and, therefore, invest into new equipment in order to inch ever closer to the goal of achieving grid parity.

What’s next at Manz Automation as you strive to improve your technologies and drive solar manufacturing innovation?

Manz will strengthen its leading market position by developing new technologies and integrated solutions. Costumers benefit from improved efficiency of their solar cells and reduced costs in manufacturing. We have introduced new products for crystalline solar cells, like wet chemical process machines with lower breakage rates and lower input of chemicals. Also our laser doped selective emitter tool, which improves the efficiency up to 0.5% as well as the contact free metallization, contribute to further progress. Additionally, the high-precision printer HAP2400, developed by Manz, is by far the most precise and fastest screen-printer on the market.

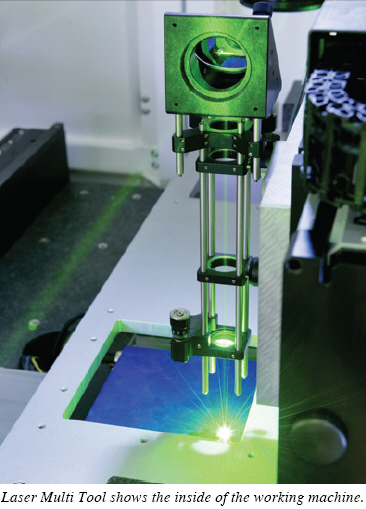

In the field of thin-film technology, we have started with the second generation of laser scribing machines with higher efficiency and throughput rates and TCO etching, which leads to higher efficiency through light trapping effect. Generally speaking, we see a strong demand from our clients to allow the existing systems to be ‘upgraded’. Due to current market situation, they want to be able to cut the costs of existing production lines and hence manufacture products even more competitive. Manz has responded to this market need and offers clients the ability to replace or upgrade their machinery within the production line.

With the recently completed know-how licensing and strategic alliance agreement with Wrth Solar, we have exclusive access to a broad range of relevant research results regarding CIGS modules and glass substrates. In company with our own long-term experience in that field, we strive to become the market leader as a provider of fully integrated, cost-effective CIGS production lines (Manz CIGSfab).

What have you been doing to grow your presence in the international solar arena?

Manz currently maintains production facilities in Germany, China, Slovakia and Taiwan. R&D is located in Germany, Israel and Taiwan. Several business units were outsourced abroad: LCD-handling was successfully relocated to Taiwan, some more products from our solar portfolio will be relocated to China and Eastern Europe within this year. This enables Manz to reduce both costs and lead times. Manz also maintains own sales and service subsidiaries in all major markets like China, Taiwan, India, South Korea and the U.S. New acquisitions are planned to strengthen our market position and to expand our product range even further. In 2009, Manz exported over 70% of overall production to international customers.

Please introduce your management philosophy that you have been pursuing.

Manz Automation views itself as a high-tech equipment manufacturer in the fields of green technology. In addition, our goal is to develop machines and systems for fast-growing industries around the world that are on the cusp of becoming attractive mass markets. In pursuit of this aim, our strategy is to innovate at a fast pace, improving existing products and creating new solutions that offer our clients competitive advantages. In this regard, our high level of technological expertise forms the foundation upon which our company is built. We are primarily focused on the photovoltaics and LCD industries, but at the same time, remain open to new trends and growth industries like the lithium ion battery market.

What are your expectations for the development of the PV market in the coming years?

We are expecting a rising demand for solar modules and cells in the future. Due to that, major investments in new facilities, especially in Asia and India, and a significant market shift towards that region will take place. We have seen a strong decline in prices for solar modules in 2009 and we expect prices to remain on that level at first before decreasing again. Furthermore, the political framework in Germany deteriorated and the subsidies of solar energy was reduced. Thus, short-term investments in new, state-of-the-art equipment are required for manufacturers to produce highly efficient solar cells and modules at attractive margins. Grid-parity will lead to an increased demand--the solar boom has only just begun and Manz Automation AG will benefit from it, particularly with regard to the cadium-free CIGS technology, which is said to become the industry standard. In the future, photovoltaic power will become an integral part of the global energy mix used to secure the supply of energy: Total crystalline solar modules and thin-film technology segment output in Gigawatt will almost octuple until 2020. Summing up, continuously improving PV technology provides an adequate response to the so-called ‘finite energy resources’.

Jeanny H. Lim is Editor-in-Chief of InterPV. Send your comments to swied@infothe.com.

For more information, please send your e-mails to pved@infothe.com.

ⓒ2010 www.interpv.net All rights reserved. |