Reported by Jeanny Lim (swied@infothe.com)

To help our readers understand you better, please give us a brief account on how the company entered the solar photovoltaic business. To help our readers understand you better, please give us a brief account on how the company entered the solar photovoltaic business.

As a specialist supplier to flat glass manufacturers and processing companies, we were again and again confronted with pre-products for the photovoltaics industry, glass playing a major role in this industry. Observing the first upswing in the thin-film technology, Grenzebach soon realized that this industry could benefit from numerous technologies used in processing architectural glass. In the last five years, the solar industry evolved to a solid mainstay in the Grenzebach activities.

You have 50 years of experience in conveying and handling technology for the flat glass and gypsum plasterboard industries. How do you meet the unique demands of today’s solar industry?

It precisely is this experience that we can directly transpose in our concepts for PV panel processing lines. Moreover, the equipment and plant we offer to flat panel display manufacturers and that are fit for use in clean room environment constitute another source we can tap in developing conveyor and handling equipment for the solar industry. On top of that, we are originating, bit by bit, other process steps such as, for example, cleaning and laser processing systems.

Could you tell us some of the competitive edges that differentiate you from your competitors in the solar market?

Our close cooperation with members in the Grenzebach group allows us to act as one-stop supplier for all thin-film solar plant processes except for the coating and chemical process equipment. With this philosophy, our end customer can focus on his specific processes, making him a unique market player, while Grenzebach handles the remaining aspects. This leaves our customer with only one contact partner with overall responsibility. In combination with an intelligent control concept and a higher-level MES system, the plant turns to a completely rounded piece of work.

In the solar market, what is your priority this year, business-wise and technology-wise?

Consistent development of other process technologies--this goes without saying. We are also working on new line concepts, incorporating MTBF and MTTR as well as real maintenance times, to optimize the line yield. So far material flow concepts have often been underestimated. An optimized material flow is way more than just conveying substrates from A to B. The Grenzebach MES system also takes a major part in this scenario.

What’s next at Grenzebach as you strive to improve your technologies and drive solar manufacturing innovation?

We set up a cost and technology roadmap to achieve a lasting reduction of the costs per watt and to specifically improve the individual processes. Our focus in this is on laser processing and on alternative encapsulation methods.

What have you been doing to grow your presence in the international solar arena?

We participate in all major trade fairs worldwide although we, as equipment supplier, believe that there is too much diversity. Such participations mainly focus on trade fairs in Asia, Europe and North America. In addition to that, we actively partake in conference events with specific presentations. In the German Machinery and Plant Manufacturers Association (VDMA), I sit on the board of the Photovoltaics Work Group.

You have a wide product range for thin-film PV modules. What are your speculations on how competition may play out among the various thin-film technologies?

Taking the current forecasts on trust, the market will develop to a 75:25 share in favor of crystalline cells. Two years ago the market situation was completely different and one expected a 50% medium-term market share for thin-film modules. It is indisputable that the low energy costs and the dramatically fallen silicon prices have considerably dampened the thin-film euphoria. I personally believe that, from an industrial point of view, the thin-film industry is an emergent industry with still substantial potential.

.jpg)

What are your expectations for the development of the PV market in Europe in the coming years?

There is no doubt that the market will prosper. In the coming years, subsidy programs will continue providing vital impulses. I believe that grid parity is within reach in regions with abundant sunshine. In my opinion, the real challenge to photovoltaics is not supplying solar power to cope with peak loads but far more to contribute to base load needs. This will then require intelligent network and supply concepts.

How do you evaluate your performance last year and how much growth do you expect for this year?

I think that many other companies had a hard go in 2009 whereas we did master the challenge very well. The engine of economic recovery has noticeably restarted this year and I expect an order income volume allowing an acceptable growth rate to our company.

What are some of the major challenges for Grenzebach going forward?

I put all my trust in the strength of the Grenzebach group. Our global presence with manufacturing locations in Europe, North America and China is a decisive advantage. Our challenge is to acquire still more process know-how to become a key supplier to this industry. Let it be understood?no turnkey supplier!

Please introduce your management philosophy that you have been pursuing.

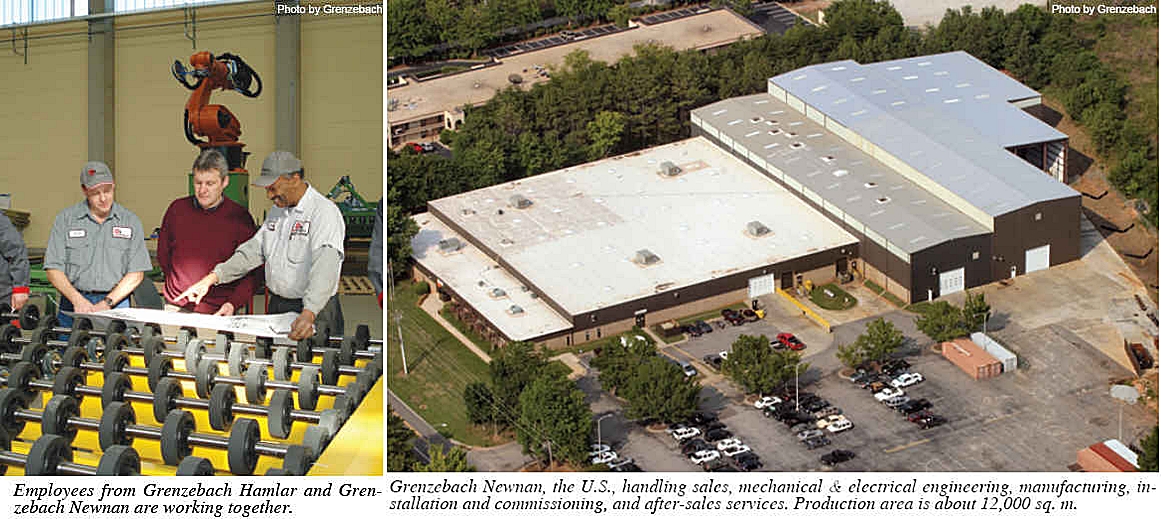

Grenzebach are a family business and also act in this sense. This is the key principle that we want to convey to our employees and to our customers alike. We value the stability of a family business with own manufacturing locations worldwide. We aspire world market leadership with innovative technologies and high-quality products that boost our customer’s success.

Jeanny Lim is Editor-in-Chief of InterPV. Send your comments to swied@infothe.com.

For more information, please send your e-mails to pved@infothe.com.

ⓒ2010 www.interpv.net All rights reserved. |