By Kevin Kayser, Leslie Bane

Expectations of Photovoltaic (PV) installers and financiers today are that their equipment (and in turn their investment) will work in the field for 25 years and will operate at maximum efficiency over this entire timeframe. However, due to module degradation over time (typically 0.5% to 1.0% per year), system owners typically model the system to have a linear loss over time. In reality, it turns out that nearly all solar PV arrays suffer from real world conditions above and beyond predicted module degradation, leading to reduced Return On Investment (ROI). These real world conditions can include system module to module mismatch, accelerated module degradation from thermal effects of bypass diodes, and environmental effects such as clouding, dirt and debris. Panel manufacturers are looking to address these inefficiencies as well as to differentiate themselves in this rapidly commoditized market space by considering integration of smart electronics.

In the past few years, several electronics vendors have introduced stand-alone options for power management in both the DC-DC and DC-AC arenas. The advantage of a standalone solution is the ability to retrofit existing installations, but the reality is the retrofit market is a tiny fraction of the potential new installations that could benefit from distributed electronics. The disadvantage of stand-alone power management is the additional cost and complexity of added wires, grounding loops, enclosures, brackets, installation time and warranties.

Integration of smart electronics is on the horizon and is the latest buzz in the industry. What smart electronics do is take advantage of power management Integrated Circuits (ICs) by building them into the panel itself, allowing the manufacturer to differentiate themselves by offering a cost effective solution that increases energy efficiency across the array while minimizing balance of system costs at the same time. Lower balance of system costs encompass lower installation and design time, less cabling/racking, lower inverter costs, and decreased panel binning costs. The allure of bringing electronics directly into the panel has arisen due to various market factors: increased price pressure, increased panel providers, and the need to differentiate among a plethora of options.

Smart Panels Ready for Primetime

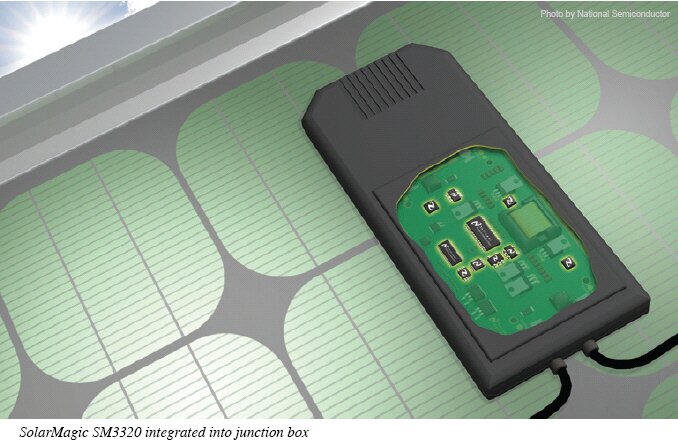

New panels, called ¡®smart panels¡¯, are starting to emerge on the market bringing the analog and power management electronics and DC-DC power optimization, directly into the panel in the form of a smart junction box. For example, HUBER+SUHNER, one of the world¡¯s largest providers of junction boxes, has developed the RADOX¢ç SolarBox NS3 that incorporates National Semiconductor¡¯s SolarMagicTM SM3320 chipset inside. The inclusion of the electronics adds additional capabilities to the junction box versus it housing the bypass diodes alone. A smart junction box is now seamlessly designed, built and integrated onto a panel increasing the panel performance and energy output. Along with HUBER+SUHNER, there are a handful of smart junction box providers on the market today, including Shoals Technologies Group, Onamba, QC Solar and more entrants on the way. New panels, called ¡®smart panels¡¯, are starting to emerge on the market bringing the analog and power management electronics and DC-DC power optimization, directly into the panel in the form of a smart junction box. For example, HUBER+SUHNER, one of the world¡¯s largest providers of junction boxes, has developed the RADOX¢ç SolarBox NS3 that incorporates National Semiconductor¡¯s SolarMagicTM SM3320 chipset inside. The inclusion of the electronics adds additional capabilities to the junction box versus it housing the bypass diodes alone. A smart junction box is now seamlessly designed, built and integrated onto a panel increasing the panel performance and energy output. Along with HUBER+SUHNER, there are a handful of smart junction box providers on the market today, including Shoals Technologies Group, Onamba, QC Solar and more entrants on the way.

Each of the smart junction box providers has its own proprietary design enabling the most efficient use of the distributed electronics. Some of these designs are single piece designs, meaning the entire unit from bypass diodes to electronics is contained in a single enclosure with one set of connectors out to the next set of panels. The advantage of this approach is the highest reliability since it has the fewest components and connectors. The alternative approach is a two piece design, which typically separates out the ribbons and bypass diodes from the electronics into a docking type solution. The advantage of this approach is easy field access to the electronics for upgrade or replacement.

With these smart junction boxes available in the industry, major panel manufacturers are seeking them out to try and add a smart panel to their existing line of products. Suntech, the global leader in crystalline module production, recently announced their joint development with National Semiconductor, the leader in distributed electronics for the solar industry. This joint effort creates a cost-effective distributed electronics solution to underperformance issues that currently reduce the performance of solar arrays. The inclusion of National¡¯s SolarMagic technology provides for higher peak efficiency (99.5%), tri-mode operation (buck, boost and pass-through mode), and mitigates current and voltage mismatch at the panel (versus string) level.

Panel Manufacturer Value

While panel manufacturers are trying to reduce their pricing to remain competitive, the need for tighter bin targets on panels based on their wattage and enhancing efficiency is adding to manufacturing costs, shaving off any margin that exists. Maintaining margins and continuing to meet price point expectations in the market are driving panel manufacturers to differentiate themselves in the market. Many panel manufacturers, large and small, have begun partnerships with DC-AC and DC-DC electronics partners to try and bring energy efficiency, and in turn differentiation, to their portfolio of panels.

Also, this smart panel solution gives panel manufacturers peace of mind that they can meet the performance specifications that are warranted with each panel. This is usually 90 percent performance for the first 10 years and 80 percent performance for the next 15 years. The addition of electronics that increase performance means that there will be fewer claims against the manufacturer since any mismatch from module degradation will be mitigated by the additional energy distribution that electronics bring.

Installer/Integrator Value

The key challenge facing installers is overall profit margin. Installers are typically small companies and exist on a cash flow business model, thus every bit of profit is essentially used towards staying in business. In addition, while today systems are priced at US$/W, as solar gets closer to grid parity, the key metric will convert to US$/kWh, which is a measure of quality and performance. Installers will need to differentiate themselves with the highest quality products that deliver the most energy to the system owners in order to survive.

Smart panels help installers and integrators maintain their Balance Of System (BOS) costs by offsetting the need to design around physical impairments such as chimneys and obstructions, decreasing cabling/wiring/racking costs as the entire rooftop space can now be utilized, and enabling a complete solution sell incorporating all quality products. The technology also allows installers to place panels anywhere on a roof, despite obstructions, tilt or orientation, and go up on the roof once for installation versus it being a multi-step process. Electrically, smart panels help BOS costs because the added intelligence per panel means string sizing can be flexible, MPPT algorithms help reduce mismatch and PV installers can improve profit margin while delivering more energy to the system owner.

Companies such as National Semiconductor are setting the bar in terms of reliability and performance, helping to ensure an industry-wide acceptance of distributed electronics. It is understood that any electronics integrated into a panel needs to match the warranty of the panels themselves, so a 25 year warranty is a must in this industry. With a 50 year history in providing electronics into the military, aerospace, automotive and now solar industries, bankability and having a balance sheet are major requirements to funding of today¡¯s large scale solar arrays. Smart electronics, once seen as a point of weakness in the system, have now reached a level of acceptance in the market due to its quality and reliability data extending throughout the warranty period.

System Owner Value

The primary focus of system owners is first the reputation of the installer selling them the system and the quality of their work and second, getting the most energy out of their investment to reduce their electric bill. System owners can now invest in smart panels from the beginning of a project to ensure that the installation meets its performance and ROI metrics year after year. Many owners project what they believe their performance ratio will be over the life of the installation or 25 years, and in the middle of this timeframe, are surprised to learn that their calculations are incorrect. Small year-by-year degradation in panels, wiring/cabling efficiency, aging, and panel-to-panel mismatch all contribute to this phenomenon.

Smart panels alleviate these issues by continuously working to find the optimum current and voltage match within the string or across strings. Smart panels installed from day one bring confidence to the owners that they will be able to increase energy harvest at the lowest cost per kWh.

Smart panels, currently in development at Suntech, Canadian Solar and GESOLAR, increase energy efficiency of an array up to 25% over the lifetime of the installation. Increased energy efficiency, decreasing points of failure in the system and enabling differentiation are all reasons why today¡¯s panel manufacturers are working diligently to deliver smart panels to the market. Look for fully-certified smart panels to hit the market in 2011.

Kevin Kayser is the marketing manager of the Solar IC Business Unit at National Semiconductor Corp (www.national.com). In this role, he is responsible for leveraging National¡¯s strength in energy-efficient technologies to develop strategies and products for efficient energy generation in the renewable energy market. Prior to joining National in 2006, Kayser held various roles in the semiconductor industry, most recently serving as product line manager for Signals and Interface products at ON Semiconductor. He also held systems and applications positions in the broadband business segment at Motorola. He holds a Master¡¯s degree in business administration from Arizona State University and a Master¡¯s degree in electrical engineering from National Technological University.

Leslie Bane is the Senior Ecosystem Strategy Manager of the Solar IC Business Unit at National Semiconductor Corp. Bane is responsible for leveraging National¡¯s strength in energy-efficient technologies to develop an ecosystem of partners and a uniquely differentiated process around the commercialization of smart panels into the PV industry. Prior to joining National, she held various roles in the high-tech industry, most recently serving as strategic marketing manager at Zoran, Inc. She has managed marketing and business development teams at start-ups and at her own company, founded in 2008. Bane holds both a Bachelor¡¯s and Master¡¯s degree in business administration from Pepperdine University.

For more information, please send your e-mails to pved@infothe.com.

¨Ï2011 www.interpv.net All rights reserved. |