by Vishal Shrotriya

The words ‘solar’ and ‘subsidies’ are usually found in the same sentence, thanks to the high cost of solar cells, more than 80% of which are based on silicon. The Photovoltaic (PV) market has grown at an incredible pace over the last few years and clocked an impressive 51% year-on-year growth in 2009. According to a recent report by Earth Policy Institute, the worldwide installed PV capacity has grown 16-fold over the past decade, primarily due to government incentives and subsidies. Even though the cost of solar cells has fallen substantially over time, government support is still necessary to enable customers to continue adopting solar energy and let PV compete with heavily subsidized fossil fuels. However, there has been a lot of speculation recently of cutting back the incentives in several countries, especially Germany and United States. This creates a problem for this nascent industry which is primarily policy driven. Thin-film PV cells based on Cadmium Telluride (CdTe) and Copper Indium Gallium Selenide (CIGS) are an alternative to the expensive silicon PVs, however, they have their own limitations that include the use of toxic materials, especially in CdTe, difficulty in scaling up production (for CIGS), and shortage of heavy and rare earth metals that might limit their production and increase the cost in the future. The words ‘solar’ and ‘subsidies’ are usually found in the same sentence, thanks to the high cost of solar cells, more than 80% of which are based on silicon. The Photovoltaic (PV) market has grown at an incredible pace over the last few years and clocked an impressive 51% year-on-year growth in 2009. According to a recent report by Earth Policy Institute, the worldwide installed PV capacity has grown 16-fold over the past decade, primarily due to government incentives and subsidies. Even though the cost of solar cells has fallen substantially over time, government support is still necessary to enable customers to continue adopting solar energy and let PV compete with heavily subsidized fossil fuels. However, there has been a lot of speculation recently of cutting back the incentives in several countries, especially Germany and United States. This creates a problem for this nascent industry which is primarily policy driven. Thin-film PV cells based on Cadmium Telluride (CdTe) and Copper Indium Gallium Selenide (CIGS) are an alternative to the expensive silicon PVs, however, they have their own limitations that include the use of toxic materials, especially in CdTe, difficulty in scaling up production (for CIGS), and shortage of heavy and rare earth metals that might limit their production and increase the cost in the future.

Advent of Organic Photovoltaics (OPV)

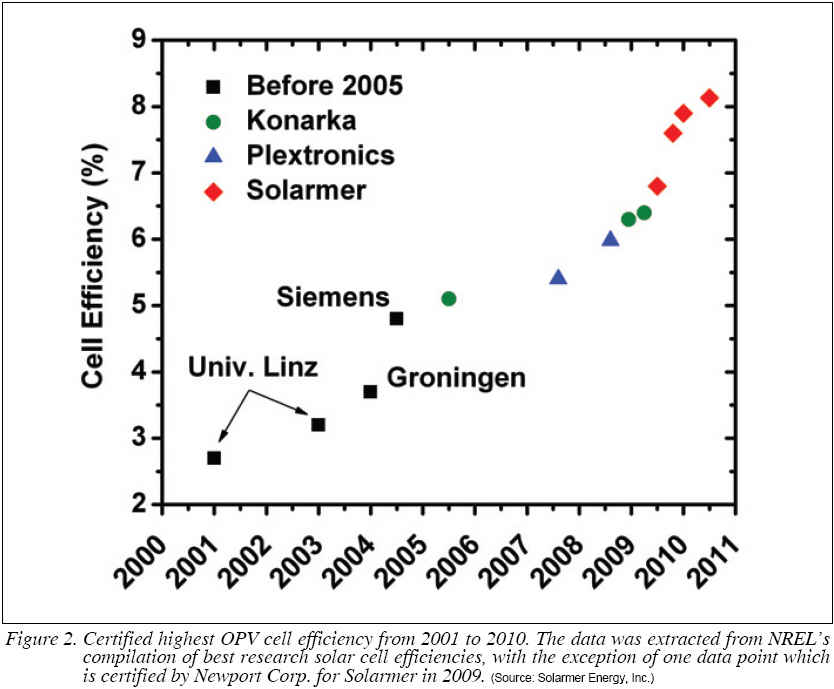

One emerging technology that is considered a viable alternative is OrGanic Photovoltaics (OPV). California-based startup, Solarmer Energy, Inc., is developing this technology for commercialization. Solarmer’s OPV cells are low-cost, have low specific-weight, mechanical flexibility, attractive colors, transparency, and better performance in low and indirect light. This is the first PV technology capable of generating electricity at a cost on par with conventional fuels, making it a cost-effective renewable energy source without government subsidies. This low-cost, combined with their light weight, flexibility, and attractiveness, makes OPV capable of being incorporated into any product or material. OPV was first reported in 1987, but their efficiencies remained low, in the range of 1-4%, up until just a few years ago. However, the emergence of several companies since 2001, including Konarka Technologies based in Massachusetts, Plextronics based in Pennsylvania, Heliatek GmbH based in Germany, and of course Solarmer Energy, among others, has resulted in a significant improvement in the performance of OPV. Today the highest efficiency for an OPV cell stands at 8.13% (certified by National Renewable Energy Laboratory, Colorado) as reported by Solarmer in July 2010. Solarmer also holds the world record for polymer OPV module efficiency at 3.9% certified by Newport Corporation.

There has been a flurry of activity in the OPV industry in the last couple of years, which shows an increasing interest in the technology and is a sign of things to come with entry of more players, especially large companies who are interested in commercializing this technology. Two new start-up companies have opened their doors recently. One of them is Eight 19 Limited, a spin off from University of Cambridge backed by the Carbon Trust of U.K. and Rhodia, a French chemicals company. The other startup is Solar Press, also located in the U.K. and seed funded by the Carbon Trust. Plextronics reported raising US$14 million in Series B funding in 2009, led by Solvay which is a chemical and pharmaceutical company located in Belgium. The biggest announcement came from Konarka which announced an R&D collaboration and strategic investment agreement with Konica Minolta in March 2010, to the tune of US$20 million. The joint development is focused on production and global distribution of high performance OPV panels. On the small molecule OPV side, Heliatek reported raising US$27 million in second round of financing in November 2009 from Bosch and BASF Venture Capital among others. Heliatek is focusing on small molecules tandem OPV cells using thermal evaporation approach and has reported 7.7% efficiency for a 1.1 cm2 cell, as part of a joint research project with the Technical University of Dresden’s Institute of Applied Photo-Physics (IAPP). All this activity is very encouraging and brings much needed resources to attack the problems that stand between the OPV and the market.

OPV Assures Own Shape

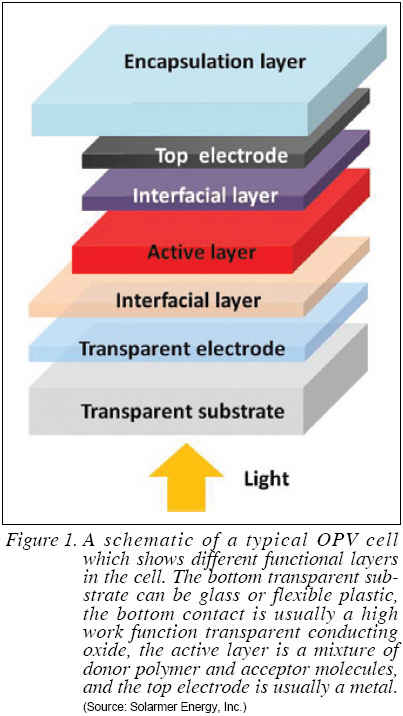

To understand the limitations and find ways to improve the performance of OPV, it is important to first understand the photovoltaic conversion process in a cell. A typical structure of an OPV cell is shown in Figure 1 where an active layer is sandwiched between two electrodes, one of which is transparent. Additionally, interfacial layers are used to facilitate the charge collection at the active layer--electrode interface. To understand the limitations and find ways to improve the performance of OPV, it is important to first understand the photovoltaic conversion process in a cell. A typical structure of an OPV cell is shown in Figure 1 where an active layer is sandwiched between two electrodes, one of which is transparent. Additionally, interfacial layers are used to facilitate the charge collection at the active layer--electrode interface.

The active layer, consisting of donor polymer and fullerene-based acceptor, converts light into electron-hole pairs which are separated at the donor-acceptor interface in the active layer and transport to the electrode to generate electricity. Increasing the efficiency has always been a challenge for OPV which lags behind their inorganic counterparts. For widespread adoption of OPV technology for power generation, efficiency higher than 10% would be needed. Solarmer has put in significant efforts to increase the efficiency and has had great success as evidenced by its records efficiency numbers. Polymers with better absorption in the solar spectrum, especially in the infrared region, need to be developed to further increase the efficiency. To put it into context, silicon absorbs light up to 1,100 nm whereas most of the current high efficiency polymers have absorption cutoff in the 800-900 nm range. Therefore, lower band gap polymers are needed. A second area of improvement is the energy lost during exciton separation process between donor polymer and acceptor molecules, usually a fullerene derivative. This loss in energy, caused by mismatching of the energy levels of donor and acceptor, results in a lower open circuit voltage (VOC) for OPV cell. To increase the VOC, both the Highest Occupied Molecular Orbital (HOMO) and the Lowest Unoccupied Molecular Orbital (LUMO) of the polymer need to match properly with the energy levels in the commonly used electron acceptor [6,6]-phenyl-C61-butyric acid methyl ester (PCBM). The trick is to increase the absorption by lowering the band gap of the polymer without affecting the efficient charge separation at the donor-acceptor interface. Collaborating with University of California, Los Angeles, and University of Chicago on new polymer development, Solarmer has pushed the OPV efficiency to over 8%. Figure 2 shows the certified OPV efficiency record over the past decade published by NREL. The highest OPV cell efficiency has increased from below 3% in 2001 to 8.13% in 2010.

For useful applications, the OPV cells need to be stable and should demonstrate operational lifetime of at least 3 years. The lifetime is typically defined as the duration over which a device or module reduces to 80% of its initial ‘stabilized’ efficiency or power output under ‘1 Sun’ illumination. Poor stability of active polymers under ambient environment and the resulting shorter OPV cell lifetime is a big problem. The lifetime of OPV is currently estimated at a few thousand hours of continuous operation under normal lighting conditions. The most direct way to improve the lifetime of OPV is to develop an encapsulation scheme with high quality barrier and adhesives. Solarmer is evaluating various encapsulation schemes which provide suitable protection from external elements. A typical encapsulation scheme for OPV is shown in Figure 3. The cell is sandwiched between two barrier films with an adhesive on each side. Several high quality barrier films are currently available; however, the encapsulation cost by using these ultra-barrier films could run into more than US$100/m2 which is a major hurdle towards demonstrating low-cost manufacturing. Several companies are focusing efforts on the development of high quality and affordable encapsulation for OPV including 3M, Mitsubishi, Vitex Systems, Toppan Printing, etc. Solarmer’s OPV have shown promising results as shown in Figure 4 where efficiency decay is plotted as a function of time for encapsulated OPV cells tested under continuous 1 sun illumination. The cells were stable for more than 2,500 hours under continuous light and show less than 10% decay in efficiency. These results are very encouraging and show that optimization of the device and encapsulation process can improve lifetime. For useful applications, the OPV cells need to be stable and should demonstrate operational lifetime of at least 3 years. The lifetime is typically defined as the duration over which a device or module reduces to 80% of its initial ‘stabilized’ efficiency or power output under ‘1 Sun’ illumination. Poor stability of active polymers under ambient environment and the resulting shorter OPV cell lifetime is a big problem. The lifetime of OPV is currently estimated at a few thousand hours of continuous operation under normal lighting conditions. The most direct way to improve the lifetime of OPV is to develop an encapsulation scheme with high quality barrier and adhesives. Solarmer is evaluating various encapsulation schemes which provide suitable protection from external elements. A typical encapsulation scheme for OPV is shown in Figure 3. The cell is sandwiched between two barrier films with an adhesive on each side. Several high quality barrier films are currently available; however, the encapsulation cost by using these ultra-barrier films could run into more than US$100/m2 which is a major hurdle towards demonstrating low-cost manufacturing. Several companies are focusing efforts on the development of high quality and affordable encapsulation for OPV including 3M, Mitsubishi, Vitex Systems, Toppan Printing, etc. Solarmer’s OPV have shown promising results as shown in Figure 4 where efficiency decay is plotted as a function of time for encapsulated OPV cells tested under continuous 1 sun illumination. The cells were stable for more than 2,500 hours under continuous light and show less than 10% decay in efficiency. These results are very encouraging and show that optimization of the device and encapsulation process can improve lifetime.

OPV’s Econimic Interests

The biggest advantage of OPV compared to other PVs is the ability to manufacture them at a relatively low-cost. However, for OPV to deliver on the promise of low-cost energy, significant innovations are needed in large-area manufacturing process. A roll-to-roll coating process for depositing various functional layers needs to be developed. In OPV devices these functional layers are much thinner than in traditional coatings--in the range of 1 to 1,000 nm which makes the coating process very challenging. Additionally, all fabrication steps need to be revisited to ensure compatibility with roll-to-roll manufacturing. So far, as the focus of research community has been on increasing the efficiency of lab-scale cells usually made on glass, very little effort has focused on studying these issues. Solarmer has set-up a roll-to-roll pilot line in Los Angeles, California specifically for this purpose. The line will not only enable detailed investigation and optimization of various processing parameters, but is also capable of manufacturing small lots of OPV panels by a roll-to-roll process. With the help of the pilot line, Solarmer will have production grade samples available in early 2011 for potential application developers.

In terms of applications, OPV has superiority over conventional PVs in the following areas: lowest-cost fabrication, easy scalability, flexibility & rollability, and attractive form factors. These areas translate into applications that cannot be addressed by conventional PVs. The most valuable long-term commercial application for Solarmer’s OPV is Power Windows--windows that generate electricity while providing protection from the light. This will be possible because of a unique characteristic of OPV--ability to be semi-transparent or translucent. Solarmer has developed proprietary transparent electrode technology, which combined with different types of polymers used for the active layer, can result in a myriad of semi-transparent and colored OPV cells as shown in Figure 5. The transparency of OPV could be as high as 50% which is very useful for Power Windows application. Solarmer is currently working with partners on turning these power windows into a reality. This technology has the potential to move the effort for net zero power buildings forward tremendously. Other potential applications of OPV include Building Integrated Photovoltaics (BIPV)--for roofing, facades, curtains, walls, etc. The major drivers for OPV’s use in BIPV are flexibility, easy installation, better performance in dim lights, aesthetic value for architects, and low-cost. Through seamless integration into a building’s normal structures, Solarmer’s solar panels will promote integration of solar technologies into any building without negatively impacting building design and appearance. The BIPV market is estimated to grow to more than 2.5 GW by 2016, based on a recent study by NanoMarkets, which presents a huge opportunity for OPV. In terms of applications, OPV has superiority over conventional PVs in the following areas: lowest-cost fabrication, easy scalability, flexibility & rollability, and attractive form factors. These areas translate into applications that cannot be addressed by conventional PVs. The most valuable long-term commercial application for Solarmer’s OPV is Power Windows--windows that generate electricity while providing protection from the light. This will be possible because of a unique characteristic of OPV--ability to be semi-transparent or translucent. Solarmer has developed proprietary transparent electrode technology, which combined with different types of polymers used for the active layer, can result in a myriad of semi-transparent and colored OPV cells as shown in Figure 5. The transparency of OPV could be as high as 50% which is very useful for Power Windows application. Solarmer is currently working with partners on turning these power windows into a reality. This technology has the potential to move the effort for net zero power buildings forward tremendously. Other potential applications of OPV include Building Integrated Photovoltaics (BIPV)--for roofing, facades, curtains, walls, etc. The major drivers for OPV’s use in BIPV are flexibility, easy installation, better performance in dim lights, aesthetic value for architects, and low-cost. Through seamless integration into a building’s normal structures, Solarmer’s solar panels will promote integration of solar technologies into any building without negatively impacting building design and appearance. The BIPV market is estimated to grow to more than 2.5 GW by 2016, based on a recent study by NanoMarkets, which presents a huge opportunity for OPV.

The color of the cells can be changed by choosing different polymers for the active layer. The transparency of the cells can also be changed by controlling the thickness of the polymer active layer, as well as the electrode thickness. Such colored translucent solar cells provide an added dimension for architects and designers for integration into various products.

In the short term, other applications are also very attractive for OPV. Consumer electronics and the portable power market, where there is a clear need for an alternative or supplement to existing battery technology, is one of the most important short term applications. OPV are best suited for these applications because of their flexibility and rollability, light weight, low lifetime requirements of these products, and ability to directly embed the charging function into the device. On average, these applications require around 2-3 watts of power and 18-24 months of lifetime, which Solarmer will accommodate with its OPV panels to be launched in 2011. First products in this category will likely be chargers for portable electronic devices such as mobile phones and PDAs. Konarka has already introduced first products in the market which include OPV-based portable chargers and OPV integrated into bags. Solarmer will introduce its own OPV products to the market in 2011-12.

OPV has been gaining a lot of attention in the last few years and establishing itself as a serious challenger to thin-film PV technologies to provide lowest-cost solar energy. Several challenges remain, not the least of which is the absence of market validation. What is needed to push this technology out in the market is partnership between companies across the value chain.

Dr. Vishal Shrotriya is leading Solarmer’s (www.solarmer.com) efforts on improving the stability and lifetime of its OPV. Dr. Shrotriya received his MS and Ph.D. in Materials Science from University of California, Los Angeles, and BS from IIT Bombay, India. He has co-authored more than 30 journal papers and patents related to OPV and has presented at several international conferences. Dr. Shrotriya also has a certificate in Management of Technology from California Institute of Technology.

For more information, please send your e-mails to pved@infothe.com.

ⓒ2010 www.interpv.net All rights reserved. |