By Dr. Tom Tibbits

Photo by Quantasol

Conventional photovoltaics has rapidly become commoditized in recent years and the crystalline silicon photovoltaic panel market is still growing fast while prices in recent years have fallen dramatically following the end of the polysilicon shortage.

However, the efficiency of the single junction silicon cell is realistically close to the practical limit that can be achieved, evidenced by the very slow upward trend over the last decade of the world record monocrystalline silicon solar cell. In 2000, the efficiency was 25.0% and this remains unchanged 10 years later. Multicrystalline solar cells are similar--the record efficiency of 20.4% has remained unchanged since 2004 (see Figure 11)). Put simply, the fundamental efficiency limit of a single junction solar cell is between 30 and 33% (depending on the spectrum used for the calculations) and, in practical terms, manufacturing a solar cell that achieves 75% of this fundamental limit is challenging. Once incorporated into utility scale systems (several MW), even the highest efficiency production solar cells have their output reduced through electrical, optical and thermal losses as a result of the modular construction of PV panels into solar farms.

Introduction to CPV

Concentrator Photovoltaics (CPV) is looking to challenge the single junction silicon and thin-film dominance in the market by developing modules and systems that significantly enhance the delivered efficiency of electricity generation. Technologically, the premise is that very high-efficiency multiple junction solar cells (originally developed for high-power, low weight space applications) can be transferred to terrestrial use if the cost can be reduced. A convenient way to reduce that cost is to use concentrating optics to focus the sun¡¯s rays onto a very small solar cell, typically by a factor of at least 500, in order to replace the expensive semiconductor solar cell area with relatively cheap optical components such as plastic lenses or mirrors. The attendant benefit of this approach is the fundamental efficiency rise that occurs when a solar cell receives concentrated irradiance--typically a triple-junction solar cell will operate at 30% efficiency at ¡®one-sun¡¯ illumination, but this can rise to >40% under 500x concentration. Furthermore, large volumes exotic materials such as high-purity semiconductors are replaced with much smaller quantities combined with the mass utilization of much cheaper commoditized materials such as glass and acrylic, improving the recyclability of CPV products.

The concept of concentration is not new--already in 212BC legend tells us that Archimedes was able to repel the Roman Empires attempted invasion of Greek-held Syracuse using an array of polished copper mirrors reflecting sunlight to set fire to the incoming Marauders¡¯s ships. Whether or not this really occurred is debatable but the principle behind it is sound.

Fast-forward to the 1970s and the concept of concentration became attractive as the mid-70s oil crisis gripped the world. Early experimentation with concentration systems was limited to silicon solar cells (the triple junction cell had not yet been invented) and, back then, silicon cells were still extremely expensive in real terms. However, the immaturity of both the silicon technology, as well as the early failure of systems, generally associated with failure modes more to do with the module assembly techniques and materials than the cells themselves, meant that the initial interest sparked by the oil-price rises waned in the early 1980s as the oil price relaxed back down.

Despite this inauspicious start, the concept of CPV has continued to be researched and championed over the years, notably at NREL in the U.S.A. and at the Fraunhofer Institute for Solar Energy systems in Germany, as well as elsewhere in both public and private companies.

With the invention and development of much higher efficiency solar cells and the recent resurgence of interest in renewable energy as a means to distract humans from their love of fossil-fueled energy, CPV firms have sprung up in the U.S.A., Europe, Australia and Asia.

Today, advanced CPV system integrators, some with many years of in-field experience, are boasting of CPV module arrays delivering electricity to the grid at efficiencies approaching 30% (this is some 40% higher than silicon panel systems) which, in areas of high irradiance, can deliver renewably sourced kWh of power at genuinely low cost--claimed in some instances to be on a par with conventionally generated electricity.2), 3)

CPV Cells

The speed of development of solar cells for terrestrial concentrator use has been phenomenal over the last decade. In 2000, the world record efficiency was ~33%, by 2010, this efficiency had risen to 41.6% with a device that was produced by SpectroLab Inc., a major supplier in the satellite solar panel industry. Today these cells are typically in production between 37% and 39% average efficiency when measured at 500x. When combined with the optical concentration systems that are being developed, along with 2-axis trackers required to keep the sun¡¯s rays incident on the optics (one side effect of high concentration is the need to keep the panel pointing directly at the sun) these systems are being touted as between 25 and 30% efficient.

What Does the Future Holds?

But what does the future hold for CPV system efficiencies? At the early stage of commercialization, CPV technology¡¯s 25% system efficiency is a great achievement, but the relentless downward pressure on cost, in particular, the levelized cost of energy, is driving system efficiency requirements to above 35%.

In order to achieve such efficiencies, advances in the optical and electrical efficiency of the systems will have to be made, but the item targeted with the highest scope for improvement is the engine of the CPV module--the cell itself.

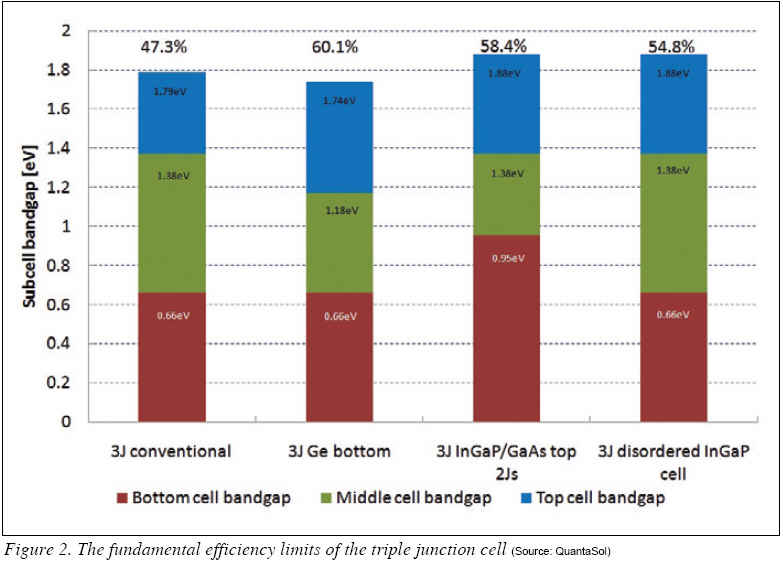

Returning to the concept of the fundamental efficiency that solar cells operate at, Figure 2 shows the fundamental efficiency limits of the triple junction cell at 500x. Today¡¯s incarnation uses Germanium (Ge), Indium Gallium Arsenide (In0.01Ga0.99As), and Indium Gallium Phosphide (In0.5Ga0.5P) as the three semiconductor junctions. However, this material combination has a fundamental efficiency limit of 47.3%, and 75% of that is 36%--pretty much where production of these devices has got to today. In other words, it¡¯s unlikely that, in a production scenario, there will be significant further improvement of the standard 3J device efficiency.

If, however, the materials used could be chosen arbitrarily, the maximum efficiency of a 3J device (based on Germanium for convenience) would rise to 60.1%, opening up the path to realistic production efficiencies of 45% or more. The goal of any work to produce a 3J solar cell based on Ge with the maximum possible theoretical efficiency is to provide good quality semiconducting material with a band gap that can be chosen to suit the application. Another approach that is being examined is the replacement of the Ge junction in a typical 3J cell with another material of higher band gap. The limiting efficiency in this instance is ~58%--see the third column in Figure 2.

Band Gap Engineering

.jpg) It is possible to change the composition of many III-V compound semiconductors in order to change the electronic band gap of the material--for example, GaAs and InAs have band-gaps of 1.42eV and 0.36eV respectively. The tertiary alloys in between have varying band gap, scaling approximately proportionally to the Indium content in the alloy. Figure 3 shows the range of materials available to III-V compound semiconductor designers. The problem arises for solar cell production in the lattice mismatch between materials?olar cells rely on very high-quality crystallinity to give the materials both the absorptivity and the electrical properties necessary for efficient operation. Even very small mismatch of crystal lattice sizes (the average spacing between atoms, or the x-axis in Figure 3) can significantly disturb crystalline structure and sharply reduce the cell¡¯s efficiency. It is possible to change the composition of many III-V compound semiconductors in order to change the electronic band gap of the material--for example, GaAs and InAs have band-gaps of 1.42eV and 0.36eV respectively. The tertiary alloys in between have varying band gap, scaling approximately proportionally to the Indium content in the alloy. Figure 3 shows the range of materials available to III-V compound semiconductor designers. The problem arises for solar cell production in the lattice mismatch between materials?olar cells rely on very high-quality crystallinity to give the materials both the absorptivity and the electrical properties necessary for efficient operation. Even very small mismatch of crystal lattice sizes (the average spacing between atoms, or the x-axis in Figure 3) can significantly disturb crystalline structure and sharply reduce the cell¡¯s efficiency.

For example, researchers at the Fraunhofer Institute for Solar Energy Systems in Freiburg, Germany, have demonstrated a 3J solar cell using lattice mismatched In0.17GaAs and In0.65GaP alloys for the middle and top cell of a 3J solar cell, which has a theoretical limiting efficiency of 53% compared to the 47% for a conventional 3J cell4). In spite of this higher limit, the most efficient solar cell in the world is a conventional 3J lattice matched device--the Fraunhofer attempt being very close, but not demonstrably more efficient 5).

A patented approach being pioneered by QuantaSol, a spin-out company from Imperial College, is the use of extremely thin layers of lattice mismatched material, not more than a few 10s of nanometers thick, which can be grown without degrading the crystalline quality because each layer is so thin. These thin layers form ¡®quantum wells¡¯ between barrier layers that are designed to relieve the built up strain in the crystal. Although they are very thin, the quantum effects also increase the absorption of the quantum wells, so it becomes possible to tune the band gap of the host solar cell according to the design of the quantum wells. If done correctly, the crystallinity is not affected at all, and the potential efficiency of the devices is very high.

QuantaSol is developing structures that modify the middle cell band gap in a traditional 3J device design, as well as approaches which use quantum well structures in all three junctions in a 3J stack. In this way significant efficiency improvements can be made to the standard 3J design which many module manufacturers are now familiar and comfortable with. QuantaSol technology delivers higher performing devices, but also, as the understanding of the CPV systems evolves, can tune band gaps to produce a solar cell such that it maximizes the output from a CPV system over its lifetime.

Because of the versatility of the quantum well toolbox, almost any solar cell architecture can be envisaged--even extending to the 4J concepts that are now being talked about as the next generation of highly efficient solar cells. These have the potential to reach as much as 50% efficiency, which, in conjunction with the best optical and electrical systems, could deliver CPV modules operating at >35% sun to grid efficiency, about double what today¡¯s best systems can deliver.

If these targets can be met, and the costs of CPV systems and their components continue to fall with the rising volumes and aggregated experience in the industry, then the future for CPV could be very bright indeed.

Dr. Tom Tibbits is Director of Product Marketing at QuantaSol (www.quantasol.com). Having spent the last 10 years working in renewable energy, Dr. Tibbits is an expert in the epitaxial design of III-V devices and has been with QuantaSol since its founding. Having been a protg of Professor Keith Barnham, QuantaSol¡¯s Chief Scientific Officer and Emeritus Professor of Physics at Imperial College, Dr. Tibbits is the architect of QuantaSol¡¯s vision to maximize energy harvesting from multi-junction solar cells by tuning material band gaps with the company¡¯s proprietary quantum well structures. He also spent a year at the Fraunhofer Institute for Solar Energy Systems, furthering developments in this area.

REFERENCES

1) Lawrence Kazmerski, ¡®NREL Compilation of best research solar cell efficiencies¡¯ National Renewable Energy Laboratory (NREL), Golden, Colorado, 2010

2) http://www.solfocus.com/en/news-events/press-releases/2010-03-18.php

3) http://www.vvc.edu/measurejj/091216_Program_Status_Report_and_Budget.pdf

4) A.W. Bett et al., ¡®Highest Efficiency Multi-Junction Solar Cell for Terrestrial and Space Applications?- proceedings of 24th European Solar Energy Conference and Exhibition, Hamburg, 2009

5) R. R. King et al. ¡®Band-Gap-Engineered Architectures for High-Efficiency Multijunction Concentrator Solar Cells¡¯, 24th European Photovoltaic Solar Energy Conf., Hamburg, Germany, Sep. 21-25, 2009.

For more information, please send your e-mails to pved@infothe.com.

¨Ï2010 www.interpv.net All rights reserved.

|