By Stephanie Rosenthal

While conventional flat panels have their undisputed market in residential installations (mostly on rooftops), CPV installations are on their way to delivering a substantial green energy source for big utilities. When it comes to large installations of several MW, conventional installations of solar panels are faced with certain disadvantages.

Efficiencies Are Less Than Ideal

15-20% for silicon and even lower (8-10%) for thin films. Additionally, PV systems can suffer from temperature degradation in hot climates, possibly resulting in markedly lower energy output. While the presence of the sun is essential for generating electricity, too much intensity can be detrimental to performance. Figure 1 shows an overview of different cell efficiencies in research.

The amount of photon absorbing material required for producing a desired amount of electricity must also be considered. Both the cost and availability of the material, as well as the extensive real estate that can be required for the installation, are primary concerns.

Recognizing that the inherent disadvantages make conventional PV less and less suited for commercial applications, solar design engineers are turning to concentrated photovoltaic to achieve higher efficiencies, obviate the heating effects of the sun and keep installations as compact as possible. As a result, CPV has evolved to the point where proprietary designs and functioning prototypes are proving the validity and cost-effectiveness of the technology.

CPV systems use concentrating optics like Fresnel lenses (which are made out of acrylic to collect sunlight) and concentrate them at magnifications up to 6,500 suns. The concentrated light is focused on an optical device that spreads the sunlight evenly onto individual cells, each of which is smaller than a thumbnail. The concentration at the cell level is upwards of 1,000 suns--on other words, the optic system produces light up to 1,000 times the normal intensity of the sun, which is then captured by substrate-based cells. Figure 2 shows the Pyron Solar HE Optics System.

The resulting modules, consisting of connected cells, are able to achieve efficiencies approaching 30% and considerable higher energy output at a significantly lower per-unit cost for the installation footprint. Obviously, the concentrating optics are most efficient when they capture the highest possible amount of sunlight at all times. This is achieved by a dual-axis tracking system that follows the sun along the horizon over the course of the seasons, and from sunrise to sunset each day. Dual-axis tracking increases the number of kilowatt-hours produced over static installations.

Another difference between conventional PV and concentrated photovoltaic has to do with the photon-absorbing material used in the cells. Instead of crystalline silicone or thin films of PV cells, CPV employs multi-junction cells that incorporate three layers. Each layer is designed to absorb a different wavelength for improved and fuller absorption of electromagnetic radiation over the solar spectrum. In short, those cells are able to generate electricity from the widest possible spectrum of the sun1).

The effort to produce a viable, cost-effective CPV system is resulting in the implementation of a number of creative approaches. To suit the target market for CPV installations (utility-scale solar developers, off-grid rural/village electrification, project developers, and larger commercial installations) one technology, employed by Pyron Solar, offers an interesting technology innovation.

CPV Innovations on the Market

The Pyron Solar system differs from all other CPV systems in the market--the initial product is a 60 kWp DC CPV generating system with dual-axis solar tracking that is protected by a number of issued and pending patents. The system is comprised of three 20 kWp DC floating arrays whose tracking system in azimuth is driven by a small 12V DC motor. Each array is 45¡¢in diameter. Photo 1 shows Pyron Solar¡¯s 20 kW full-scale prototype under construction at SDG&E Mission Skills training center.

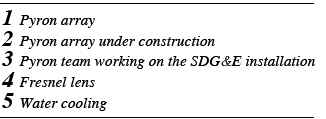

Pyron has a very low-profile dual-axis tracking system, accomplished by nesting its modules, ideally spaced, on a floating ring array. The water provides many advantages: highly efficient cooling, establishment of a perfect horizontal solar tracking reference, earthquake protection (with automatic re-alignment), and low friction turning surfaces for the drive motors, to name a few. Furthermore, Pyron incorporates various elements into the water to retard evaporation and protect against freezing conditions.

A full-scale prototype is currently under construction in San Diego in partnership with San Diego Gas & Electric (SDG&E). Photo 2 and Photo 3 show Pyron Solar team members working on the installation. When fully operational later this year, the resulting 20 kilowatts of solar-generated electricity will be used to help power SDG&E¡®s Mission Control/Skills Training Center. This new technology has the potential to cut solar power costs significantly as compared with conventional rooftop flat-panel photovoltaic systems. The savings are due in large part to the use of concentrating optical devices rather than more expensive semi-conductor material water is used as a passive coolant to disperse the heat generated by the photovoltaic cells, thereby preventing overheating of critical system components and dramatically increasing efficiency.

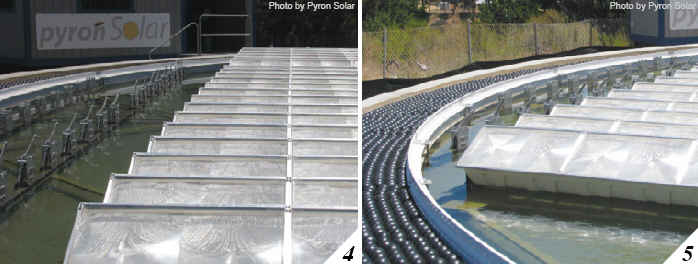

Pyron utilizes a patented, short focal length, acrylic concentrating lens system for its primary optics as shown in Photo 4. It is designed to reflect and refract in order to raise the sunlight concentration to 6,500 suns on a pinpoint of light, which first hits an optical device. This optic captures the sunlight and spreads it evenly on a small solar cell, and the resulting combination of optics and accompanying photovoltaic cells are grouped into modules of eight units.

The modules are essentially troughs that rotate around their longitudinal axis to track the sun in elevation (dual-axis tracking system). Figure 3 describes how the lenses and HE Optics are assembled into modules that rotate on their longitudinal axes. Figure 4 shows how modules are assembled into a structural ring to form an array that floats and rotates around its vertical axis.

The short focal length design of Pyron allows the entire platform to be close to the ground. Windstorms have proven to be the pitfall of many previous concentrator designs, and the Pyron System eliminates this problem: standing only 16 inches high, it presents an extremely low profile to not only windstorms, but hailstorms and sandstorms as well. Furthermore, the previous problem of vertically arrayed, billboard-sized systems that cast very large shadows is also minimized with the Pyron Solar system, and the short focal length makes tracking more simple and reliable.

Unique Cooling Method

Competing concentrator PV designs suffer from a very narrow operating window due to wind speed. These air-cooled systems require a certain amount of wind speed to cool efficiently, yet their cantilevered design suffers from wind-loading restrictions that require them to shut down in winds of fairly low velocity; conversely, if the wind speed is too low with these systems they suffer efficiency losses in the PV cells due to high temperatures. The Pyron System, on the other hand, is passively water-cooled--water is far more efficient as a heat-transfer medium than ambient air, and the power generated will exceed the power of otherwise equivalent air-cooled concentrating PV systems thanks to lower cell operating temperatures. Photo 5 shows the Pyron System floating on water that functions as passive cooling element.

Even more remarkable is the output-to-land ratio, or so-called‚ ¡°footprint¡° of this new technology. Pyron Solar provides the smallest footprint in the industry, meaning that it requires the smallest area of land per installed MW peak only 3.1 acres are needed to install one MW.

Huge Market Potential for CPV

According to the Concentrated Photovoltaics Industry Report 2010, CPV installations in the U.S.A. will grow from 1.5 MW to 75 MW in the next five years. If installation patterns in the PV industry are anything to go by, this will represent just 8% of total CPV installations by 2015.

This is what clean energy on a large scale is looking for: a higher power density and more economical use of land, resulting in a potentially lower Levelized Cost of Energy. As the most efficient system in the already-efficient CPV market, Pyron Solar will be on the cutting edge of clean energy technology for years to come.

Stephanie Rosenthal is President & Chief Operating Officer of Pyron Solar III, LLC (www.pyronsolar.com). Rosenthal has over 15 years of experience in German manufacturing of UV/Electronic systems with focus on efficient automotive manufacturing solutions (coached by Volkswagen). She holds BA in Economics, University of Aachen, Germany.

Reference

1) Multi-junction III-V cells are e.g. a product of Spectrolab, Inc. Competing concentrator cells, originally developed for space and terrestrial applications, can be obtained from other manufacturers as well. The Spectrolab cell holds the current record for conversion efficiency over 39%. The efficiency of the Spectrolab cell has been measured and confirmed by the U.S. Department of Energy¡¯s National Renewable Energy Laboratory (NREL).

For more information, please send your e-mails to pved@infothe.com.

¨Ï2010 www.interpv.net All rights reserved.

|