By Hai Chang

Solar Energy & Grid Parity

There’s no doubt that the solar Photovoltaic (PV) industry is hot. According to Solarbuzz, LLC, an international solar energy research and consulting company, world solar Photovoltaic (PV) market installations reached a record high of 2,826 MW in 2007, representing a growth of 62% over the previous year. World solar cell production reached a consolidated figure of 3,436 MW in 2007, up from 2,204 MW a year earlier. The PV industry raised nearly US$10 billion in 2007 and generated US$17.2 billion in global revenues in 2007. The U.S. has set 2015 as the goal to reach grid parity (that point where solar electricity is equal to grid electricity) while other nations predict reaching it as soon as 2010. Regardless, it’s clear there will be an exploding demand for PV electricity in the near future.

Top manufacturing executives in the solar industry are challenged to find the most effective tools and processes to gain more productivity and decrease costs within a set budget. This article addresses how the use of automation within this new industry can provide these top executives with the key components to maximize factory throughput, drive down costs and improve efficiencies.

Introduction Stage & Lessons Learned

As an industry considered to be in the introduction stage of its life cycle, its manufacturers are now contemplating the next critical steps in their production processes to remain competitive and prepare for this demand. As stated above, the key for these manufacturers will be driving down costs, maximizing factory throughput and improving efficiencies. Automating solar processes will be the solar manufacturer’s first line of attack to accomplish this. Manufacturers will be wise to reap the benefits of experience from more mature industries that have been through the rapid growth associated with a developing and maturing product line. Industries such as the semiconductor, disk drive and flat-panel display industries have paved the way. Each has experienced extreme rapid growth and has used automation to attack the ‘Big Three’ drivers: improving efficiencies, lowering costs and maximizing throughput.

Although there are many differences between solar and semiconductor manufacturing over all the processes are similar in that they manufacture sensitive wafers at their core. While semiconductor production requires very clean environments and single wafers can cost thousands of dollars, the solar industry does not require such stringent cleanrooms and a single wafer may cost US$5. However, like the semiconductor industry which started out with small fabs & larger wafers then moving to larger fabs and smaller/thinner wafers the solar industry will also follow this progression. These similarities coupled with the ‘Big Three’ drivers any growing industry faces are reasons enough for solar manufacturers to learn from the past. That past experience points to automation.

“We believe that the U.S. solar manufacturing environment today is verysimilar to that of the semiconductor and electronics environment of the ‘80s,”says John Dulchinos CEO and President of Adept Technology, a leading robotics manufacturer which recently announced its Adept Solaris line of robotic systems designed specifically for the solar industry. “During that time they began to make significant investments in automation, and thus realized a more aggressive curve in driving down costs. The solar industry is at a similar situation now.”

Automating Solar Manufacturing

Although demand for solar products is rapidly increasing, manufacturing solar panels is still more costly than producing electricity with fossil fuels, which is why governments provide economic incentives. However, availability of these incentives is tenuous and manufacturers preparing for the increase in demand are wise to consider all their options to lower costs.

Throughput, Costs & Efficiency

The largest costs associated with manufacturing involve throughput, quality and labor. When trying to drive costs down manufacturers need to address material cost, overhead cost and labor cost. Automation addresses all three.

The most effective way to lower your overhead costs besides getting a much cheaper facility is to get much more throughput out of the same amount of facility space. If you have a fixed expense and drive twice as much through the same amount of space it effectively cuts your overhead cost in half. The fundamental value of automation and robotics to any production line is the ability to produce a much larger volume in the same amount of floor space.

The best way for manufacturers to lower material costs is to have very efficient processes with very little scrap material. Ideally, you want to stop producing bad parts but if you do produce them at any point in the process find that point and resolve the issue before the product continues through the rest of the process. Basically weed out that process or step that is causing the bad part. Automation affects throughput and material costs in that they do a better job of handling products than manual labor. Robots have less handling defects in the process and reduce scrap due to handling errors. With inspection technologies, using vision as an example, manufacturers can inspect a product at each step of the process and verify that the part is worth allowing it to go to the next process steps. This technology allows manufacturers to catch bad product and analyze the process.

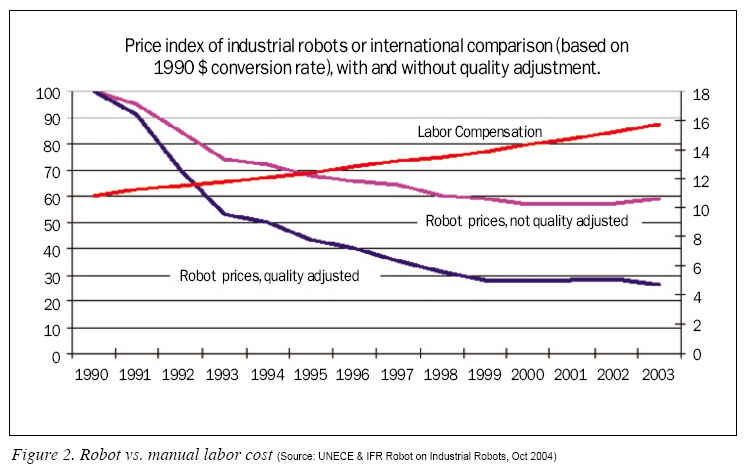

Automation allows for the production of better quality products at a faster rate while lowering overall fixed costs and material costs. Robotic handling with vision inspection is more consistent than manual labor. For example, automated vision inspection applies the exact same vision criteria each and every time whereas manual labor tends to have a lot of variability in the inspection process. Manual labor is inconsistent as no two human operators are the same. One person may have a less discriminating eye than another. Vision can use both infrared and standard wavelength for inspections. Today, around 35% of all the robotics systems Adept Technology supplies have integrated image processing for inspection and guidance. Coupled with the decrease in the price of robots and increase in cost of labor (as in Figure 2), automation inspection proves to be faster and more consistent and will serve the solar industry well.

Automation Opportunities in Solar Manufacturing

Some examples of various steps in the solar manufacturing process that will benefit from automation include but certainly are not limited to wafer handling between the process steps, box/tray/boat loading & unloading, and vision guided conveyor loading & unloading. Each benefits from the automation process by virtue of automation’s speed, accuracy and efficiency. One such application is a cell being used in an inspection system to load and unload inspection machines that are also sorters that will grade the cells and then sort them into different bins. Another application example is a cell using robotics to transfer cassettes containing solar wafers to a machine where a process occurs, such as putting an anti-reflective coating on the cells, and then the robots transfer the completed product to conveyors in trays or boats to be sent to the next step or process machine. The obvious advantage being again speed, accuracy, efficiency and the ability to work 24/7 if need be. Additionally, certain processes produce cells that are 150℃ making automation the only way to handle them without the need to wait for a cool down allowing manual manipulation.

Robots are being utilized now within the solar industry such as Adept Technology’s robots currently handling, inspecting and sorting solar cells in all the steps in the process at several leading solar manufacturer’s facilities. The robots are doing a faster job of transferring solar cells from one process to the next. With advanced computer algorithms and gripper technology robots are able to handle the delicate job of handling solar cells more reliably and consistently than people can. Because of that, it allows the cells to be transferred more quickly from step to step with less breakage. As solar manufacturer’s move to thinner and thinner silicon solar cells they will require even more delicate handling because these cells will be more fragile and brittle. The difference between a 150 micron solar cell compared to a 300 micron thick cell is substantial and automating this process will be vital.

Manufacturers in the know understand that the only way that they can be competitive in the global economy is by automating which allows them to maximize throughput in the factory, lower scrap rate and reduce labor costs. A typical robot cell can process approximately 45-75 solar cells a minute significantly faster than a manual process. A typical robot solar handling cell will range from US$100,000 to US$200,000 which considering the cost of paying and maintaining multiple employees to do the same job is extremely cost effective and a good return on investment.

Taking a lesson from previous industries that adopted automation is a good bet for solar manufacturers.

State-of-the-art technology using vision guidance for fast, precise motion will be vital for manufacturers of solar wafers and solar cells, as they adopt new manufacturing equipment to maximize production throughput. Automation will be key to reaching grid parity.

Hai Chang was appointed Managing Director of Asia Operations at Adept Technology (www.adept.com) in July 2007 and is also responsible for Adept’s business in the solar and disk storage industries in North America and Asia. In his 14-year career with Adept, he has held multiple technical and management roles in customer service and sales. In the 5 years prior to joining Adept, he was an Adept customer, working as an applications engineer and automation consultant in both higher education and industry. Chang holds a B.S. degree in mechanical engineering from University of California Berkeley and has completed his M.S. coursework in manufacturing engineering with an emphasis on robotics and controls at University of California Los Angeles.

For more information, please send your e-mails to pved@infothe.com.

ⓒ2010 www.interpv.net All rights reserved.

|