A homogenizer made out of N-BK7 for CPV

By Steffen Reichel, Ralf Jedamzik, Volker Wittmer

Concentrator Photovoltaic

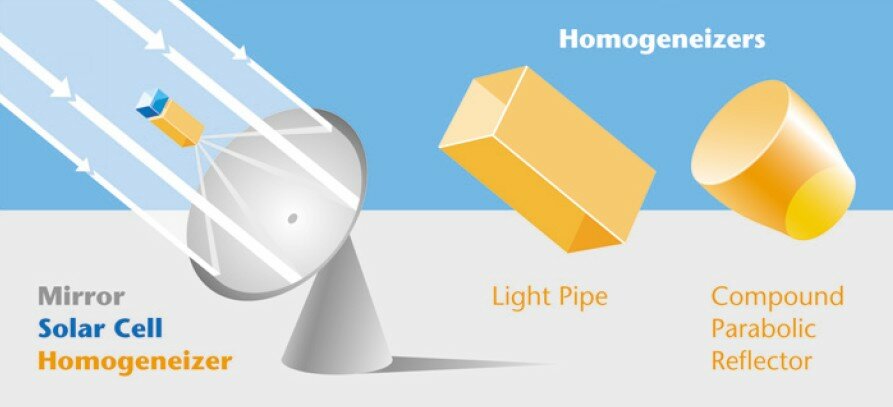

The fundamental concept of a Concentrator Photovoltaic (CPV) is the use of a solar cell made out of a direct bandgap semiconductor illuminated with concentrated sunlight, see Figure 1. The direct bandgap semiconductor has the advantage of much higher efficiency compared to Si (silicon)-based solar cells, which are indirect bandgap semiconductors. The much higher price of direct bandgap semiconductors is compensated by concentrating the sunlight onto the photovoltaic cell, thereby increasing the cell’s energy production. The goal is to have a comparable cost to performance ratio with Si-based solar cells. The concentration of the sunlight can be done by mirrors or by lenses (called primary optics). Typical concentration ratios are between 500:1 and 1000:1 and can be even higher.

Figure 1 illustrates a mirror focusing (concentrating) the sunlight onto a homogenizer (so-called secondary optics). Doing so, the sunlight is homogenized so that the solar cell is evenly illuminated and thus the efficiency increased1). Furthermore, the homogenizer increases the acceptance angle resulting in an intensified insensitivity of the whole system to fabrication and construction tolerances. Examples for a homogenizer are light pipes or compound parabolic reflectors2) which are typically made out of glass, see Figure 1. Due to the strong concentration of the incident solar energy, the glass of the homogenizer must withstand large irradiances (typical irradiances are between 1 to 10 MW/m2) and must transmit the solar spectrum from 350 to 1900 nm.

Figure 1. A CPV system using a mirror (primary optic) for sunlight concentration showing a homogenizer (secondary optic) as well as the solar cell (left). Illustration of two possible models of homogenizers (right) (Source: Schott)

N-BK7 as Concentrator Material

As described earlier, the materials used for secondary optics (homogenizer) need to withstand concentrated sun irradiances of up to 10 MW/m2 with a significant amount of this radiation falling in the UV spectrum. As polymers typically have large solarisation effects, glass should be used. From the literature3) it is known that intense UV radiation can lead to defect-center generation in optical glasses (as well as polymers), reducing the transmittance of the glass at the UV transmittance edge and in the visible spectral range. This effect is even more critical for polymer materials. The higher this transmittance loss, the lower the power output of the solar cell. This so-called “solarisation effect” is known in microlithography due to the use of UV radiation in microlithography fabrication methods. In the “i-Line lithography”--working at a wavelength of 365 nm--multi-component glasses are optimized for low solarisation behavior.

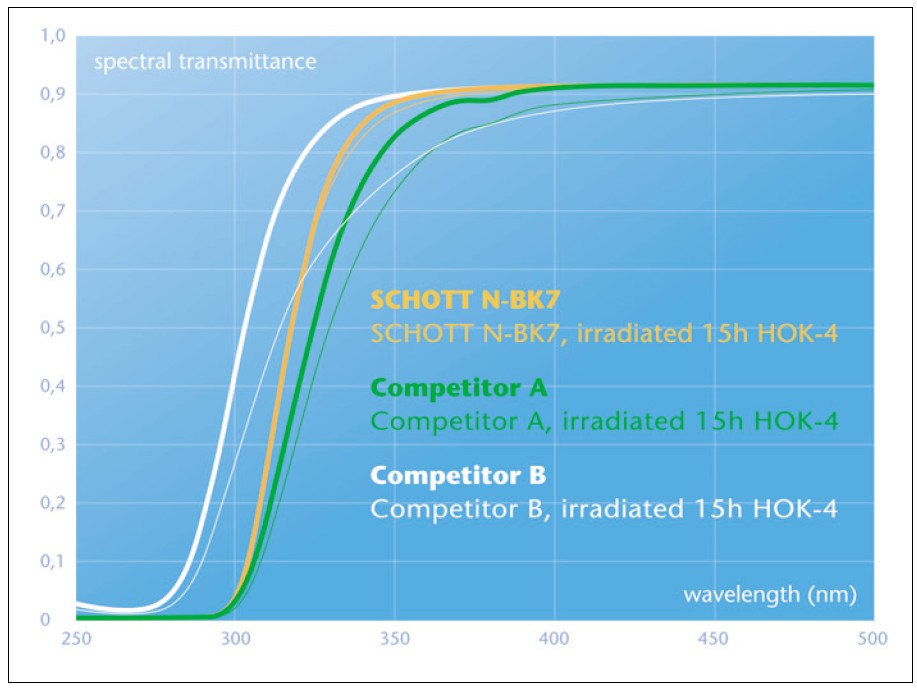

Solarisation of glasses used in microlithography is usually tested using a strong UV-lamp. At SCHOTT, the samples are placed at a fixed distance of 7 cm from the illumination source-- HOK-4 lamp with a power density of about 2 kW/m2--or a duration of 15 hours.

The radiation density within a concentrator device is some orders of magnitude higher compared to our standard HOK-4 test. The fraction of UV radiation in the wavelength range from 300 to 400 nm is still about one fifth from the total radiation, e.g., 2 MW/m2 assuming a total power density of 10 MW/m2. The glass has to withstand not only 15 hours of continuous radiation but up to 20 years of daily use.

Figure 2. Spectral transmittance curve of SCHOTT N-BK7 in comparison with competitor materials (equivalent to N-BK7) before and after 15 hours of UV irradiation with a HOK-4 lamp. (Source: Schott)

The solarisation behavior of optical glass can be influenced by direct modification of the composition of the base material. The modified composition of SCHOTT N-BK7 has proven to be a good example for an excellent solarisation behavior. Figure 2 shows the comparison of the solarisation behavior of N-BK7 to competitor materials. All samples have been irradiated using the HOK-4 lamp for 15 hours. The transmittance has been measured before and after irradiation. In Figure 2, the different behaviors of the materials can be clearly seen. The competitor materials show a strongly reduced transmittance from the UV edge up to at least 450 nm after 15 hours of irradiation, whereas the N-BK7 shows only a limited reduction of transmittance. At 350 nm the competitor glasses have a transmission loss of up to approximately 13.2% due to solarisation whereas N-BK7 has a loss of only 1.6%.

As described, the maximum power density of the HOK-4 lamp is much lower compared to the real situation within a CPV. Nonetheless, SCHOTT N-BK7 is considered to show the best performance under high power UV irradiation conditions within solar concentrator elements--like a homogenizer--and it should be emphasized that N-BK7 can be produced very economically.

CPV systems concentrate solar radiation evenly onto a secondary optic with the goal of increasing the system’s efficiency. Due to the high optical power (irradiances between 1 and 10 MW/m2) the UV radiation produces a solarisation effect that leads to reduction in the transmission in glass and polymer materials. This effect is much stronger in plastic than in glass, which is one reason why glass is the material of choice for such applications. But even glass can show different strengths of the solarisation effect, SCHOTT’s N-BK7 shows a very small solarisation effect compared to competitors’ N-BK7 glass equivalents. Therefore, N-BK7 glass from SCHOTT is especially suited for use as a homogenizer (secondary optics) in CPV systems (see main artwork).

Dr. Steffen Reichel is Senior Manager Business Development and Product Manager Optical Filters at SCHOTT AG business segment Advanced Optics (http://www.schott.com/).

Dr. Ralf Jedamzik is Application Manager at SCHOTT AG for the business segment Advanced Optics. Dr.-Ing. Volker Wittmer is Project Manager at SCHOTT AG for the business segment Advanced Optics.

REFERENCES

1) R. Winston, J. Minano, P. Benitez, Nonimaging Optics, Elsevier Academic Press, Burlington, 2005

2) W. Cassarly, Design of Efficient Illumination Systems, SPIE Course Notes SC011, 2009

3) H. Bach & N. Neuroth (Editors), The properties of optical glass, Springer Verlag, Berlin, 1998

For more information, please send your e-mails to pved@infothe.com.

ⓒ www.interpv.net All rights reserved

|