Reported by Jeanny H. Lim (swied@infothe.com)

.jpg)

The global economic slowdown and the Eurozone debt crisis have curbed government investment in renewable energy including solar. In addition, the rapidly falling prices of solar panels due to a supply glut are severely affecting solar panel manufacturers. This is a difficult and uncertain time for solar. How is Hyundai Heavy Industries weathering the storm in the struggling solar market?

Yes, it’s definitely a tough, unpredictable time for solar. In this time of uncertainty, we think we need to take advantage of this time to further strengthen our core competencies. We’re shifting our focus from capacity expansion to technology innovation in order to bring the cost down by improving module efficiency and reaching economies of scale, which will lead to lower cost per watt.

In addition, we are focusing on producing products with homogeneous quality, which means we’ll cut the number of products that are unmarketable.

Through working on improving module efficiency and product quality, we will better manage the inventory with less stock of unsalable products.

Even in this difficult time for solar, Hyundai Heavy Industries is keeping its commitment to solar energy. Where do you plan to put your focus to grow your solar business?

If your price is higher than what the market will bear, you’ll lose your customers. If the solar module prices are US$1 per watt, we’ll strive to bring our prices further down to, say, 80 US cents per watt. Otherwise, you’re not going to make any profit. Technology innovation that we are working on will result in improved efficiency and reduced stock of unsalable products, thus contributing to lowering the price than the competition.

.jpg)

The recent change in our organization just reflects that─our firm determination to focus on technology innovation. We’ve moved the Solar Energy Research Center and the Wind Energy Research Center, which were originally sub-units of the bigger Technology Research Center, under the roof of the Green Energy Division. This means we are putting manufacturing and research under the same division, and it is a significant change for us. The Solar Energy Research Center is based in Eumseong, North Chungcheong Province, South Korea and the Wind Energy Research Center is located in Gunsan, North Jeolla Province, South Korea.

Along the way, there will be investment made into improving the existing production lines to facilitate our efforts to improve efficiency.

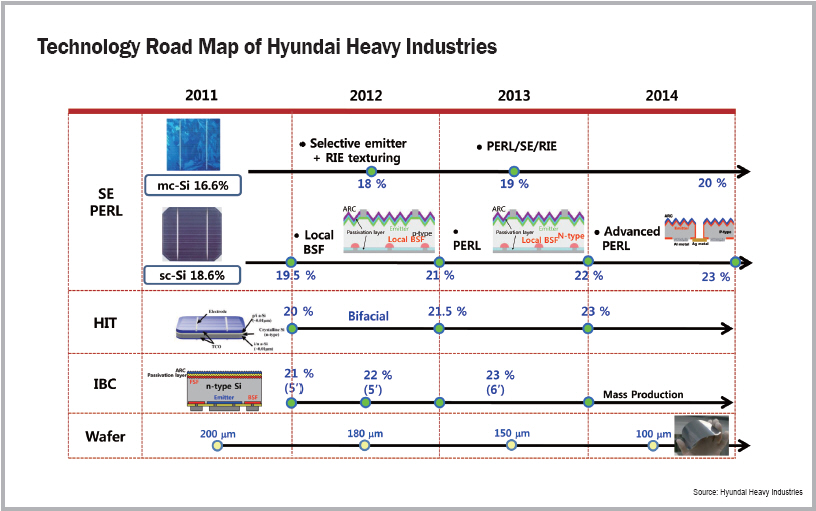

From April this year, we are manufacturing monocrystalline solar cells of 19.5% efficiency, the world’s best under mass production.

Which overseas markets are you targeting?

We are targeting Europe, the U.S. and Japan.

.jpg)

Recently, however, the Middle East solar market has been quickly getting on our radar screen. In the Middle East, the transition to solar energy has begun and the market potential is huge there. Moreover, the Middle East is where Korean companies have been building strong credits through construction projects. So I guess the Middle East market should provide Korean companies including Hyundai Heavy Industries with a great opportunity to grow their solar businesses. Plus, the harsh environment, such as the super hot weather, may work for the Korean companies because it might make it difficult for other companies to enter.

We will keep an eye on the Middle East market and have ourselves prepared.

Hyundai Heavy Industries has ventured into thin-film solar. What’s behind this move?

PV applications are transitioning from large-scale PV plants to building-integrated systems where thin-film PV modules are ideal for due to their properties such as flexibility, good power-weight ratio and resistance to radiation. In addition, thin-film PV modules have a longer power-generation time and can work in partial shade, which makes the cost-effective PV technology applicable to indoor use.

To meet the growing demand for thin-film solar technology, we’ve expanded our product offerings by adding CIGS thin-film solar modules to our existing crystalline silicon solar module portfolio.

We had evaluated types of major thin-film solar technologies before we decided to go with CIGS technology. In our view, silicon-based thin-film and CdTe solar cells have issues with efficiency and quality while CIGS has been able to reach higher efficiencies and requires less toxic cadmium to produce.

To manufacture state-of-the-art solar modules with CIGS technology, we chose to partner with Saint-Gobain to form a 50-50 joint venture called Hyundai Avancis.

We believe our continued efforts to diversify our product offerings will meet the solar needs of customers in all the markets we serve today and those we will serve tomorrow.

Could you tell us more about Hyundai Avancis, a joint venture created through partnership between Hyundai Heavy Industries and Saint-Gobain? What are your expectations for the new joint venture?

In October 2010, Hyundai Heavy Industries and Saint-Gobain, one of the world’s leading providers of construction and automotive glass, agreed on a partnership. The partnership took the form of a joint venture under the name of Hyundai Avancis, with both parties equally represented─both investing US$101 million. The capital contribution has been completed in March 2012.

In April 2011, Hyundai Avancis held a ground-breaking ceremony for a CIGS module plant with an annual output of 100 MW in the Ochang Science Park in North Chungcheong Province, South Korea. The construction of the factory has been completed this March.

The first Hyundai-Avancis CIGS module, which will be available this November, will go through tests including IEC, CE and CSA and come in three types of 110 W, 120 W and 130 W. The 130 W is expected to have the world’s highest efficiency of 12.3%.

What are some of the competitive advantages that differentiate Hyundai Heavy Industries in the solar market?

Hyundai Heavy Industries is one of the top companies in heavy industry and a leader in shipbuilding. As a long-established, large corporation, we can sustain long-term, consistent investment in technology unlike other players established only for solar who are severely affected by the ebbs and flows of the solar market. Plus, Hyundai spirit is patience and persistence. It is also deeply rooted in Heavy Industries’ culture. Once we are committed, we spare no efforts to achieve and deliver the very best in technology, and this is why we are constantly improving both in terms of research and development and in production, as well as in terms of our business processes.

Importantly, solar panels have a long warranty of up to 25 years. Important questions you should ask: a) How long has the company been in business? b) Is a 25-year warranty worth anything if the company has been in business for 2 years or less? C) Will the company be around to honor your warranty? So it is wise to buy from a reputable company with a long history to ensure your warranty is worth more than the paper it is written on. Hyundai Heavy Industries is differentiated in terms of reliability and for us, reliability means doing what we’ve promised.

In addition, we are one of the few companies who can offer premium solar products ─we can provide the market with solar cells with the world’s highest efficiency of 19.5% under mass production. And we are the only South Korean company to have completed the whole solar value chain from polysilicon and ingot/wafer to solar cells and modules to system installation and operation. Moreover, we have both crystalline silicon and thin-film solar modules on our product offering, the first in South Korea.

Continuing on our efforts to expand our business in renewable energy, we are planning to enter into inverter and energy storage businesses. We think we can benefit from our 30 years of expertise in production, transportation and conversion of power.

Jeanny H. Lim is Editor-in-Chief of InterPV. Send your comments to swied@infothe.com.

For more information, please send your e-mails to pved@infothe.com.

ⓒ2011 www.interpv.net All rights reserved. |