Arnold Group is already known for its technology in the mechanic cutting and grinding/polishing of poly-, mono- and multicrystalline silicon ingots. Peter Weier, Head of Business Unit Silicon Processing and Automation of Arnold Group, announces Arnold goes into Asia expanding its business in a conference call interview with INTERPV.

Reported by Stella Lee (PVed1@infothe.com)

.jpg)

Please tell us about your business briefly. Please tell us about your business briefly.

Herbert Arnold GmbH & Co. KG, was founded in 1950 in Weilburg, Germany. Nowadays the Arnold Group is one of the worldwide leading manufacturers of burners, tools and machines as well as ready-to-use systems for customers in the area of photovoltaic and solar thermal energy, glass and quartz glass processing, fiber optic and the automotive industry.

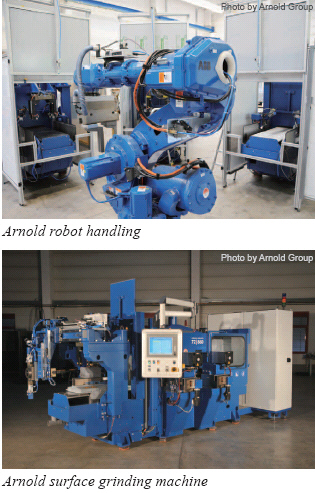

The core competence in the area of photovoltaic is the mechanic cutting, grinding and polishing of mono-and multicrystalline silicon ingots and blocks. The main capabilities of Arnold include innovative single machines, which could be supplied according to customer’s specification and requirements if requested. Furthermore, Arnold offers complete processing centers and tailor-made complete systems, including the automatic connection of different production processes and intelligent production management systems. It is a matter, of course, that international support and services are a part of our innovative products, planning and consulting, too.

What makes you different from your competitors?

As one of the few internationally accepted companies, Arnold Group offers process and automation technology for the wide spectrum of processing silicon blocks in the area of mechanical cutting, grinding and polishing from one source. This means, besides the development, design & production of machines and software for the process technology, we combine it with robotics to come to fully automatic processing centers. In the 1990s, the Arnold Group was the first manufacturer worldwide offering an automated loading and unloading station for cutting blocks, the cropping center.

Asian products hit the market these days. What are some of the changes you’ve seen recently in the PV industry?

Germany is still the largest solar market worldwide. Internationally and traditionally, Germany is leading in machine construction. Nowadays, China is deemed to be the world’s biggest manufacturing market for wafers, cells and solar modules. Not only the Chinese manufacturers, but also companies from Taiwan, India and other Asia countries plan to expand their productivities and lay their focus on the well- proven quality ‘made in Germany’. Our fully automatic production machines differ from the Asian processing machines by an explicitly higher productivity. Due to the possible economization, the higher purchase price could be redeemed quite fast.

Do you expect growth in the global market volume of PV power this year?

The latest international occurrences, especially the catastrophe in Japan, caused a new, worldwide discussion regarding energy of the future.

Simultaneously, people developed much more sense of responsibility to the environment, thus causing further impulses to the photovoltaic market within the renewable energies. From our point of view, this means a huge increase for the photovoltaic market─not only in the next years.

Will solar reach grid parity soon? Will solar reach grid parity soon?

From the global view, energy will become more expensive. However, the grid parity will be achieved earlier than predicted years ago. Consumers from the public fields, commerce and industry, will develop alternatives to the previous energy concepts. End customers will switch to providers of so-called green electricity and install their own PV plants. Nuclear phase-out will increase the conventional electricity tariff, also in order to finance the change to renewable energies, especially photovoltaics. The required grid parity is anticipated to be achieved in a few years.

How will the solar industry look in 5 years from now? And your company?

Under the roof of the worldwide semiconductor alliance ‘SEMI’, the interest group ‘Crystalline Cell Technology and Manufacturing’ (CTM)─a European initiative of leading companies in the photovoltaic industry─has formed up. Each year, an ‘International Technology Roadmap for PV’ (ITRPV) is published. This is a technological view of the complete revenue for the photovoltaic industry. Herein included are research approaches, demands for further developments of c-Si solar cells, especially materials, processes and products with the aim to render a future increase possible with significant cost reduction per piece. Manufacturers have to abide to this demand in order to survive on the market.

As an innovative partner, the Arnold will continue offering new machines, new processes, new techniques for the photovoltaic field in future. Due to optimized production methods, a higher capacity by using less machines will be possible, making a contribution to achieve the grid parity.

What is your strategy to enter the Asian market? What is your strategy to enter the Asian market?

Arnold is one of the pioneers having supplied high-capacity processing machines for years to the Asian market. Thus Arnold follows the strategy: Quality instead of quantity. Also, in future, Arnold is offering machines on the Asian market which excel exclusively by high throughput with constant high product quality and extremely high process safety. In return, this means considerable advantages for the customer. An Asian customer has calculated a 2.5 up to 3 fold higher throughput of the machine compared with the machine of an Asian competitor.

Thanks to new technologies in the Arnold machines, not only less machines linked with less consumption goods will be required to obtain a comparable result, but also sufficiently smaller industrial space, less raw material silicon and finally even a smaller number of staff. The initial higher investment costs pay off very fast and over a long period. Especially for the Asian market, Arnold has hired qualified Asian employees for sales and service. Customer visibility and activities are generally enforced in Asia.

What do you want to say to the target customers in Asia?

According to the study of the ‘ITRPV Roadmap’, quality demands change very fast. This means in the near future only wafers of high quality with very tight measuring tolerances and extremely high demands upon quality will be sold. All Asian manufacturers we recommend to orientate themselves at those parameters of the roadmap in order to sell their products successfully in future.

What else is important? It should be using exclusive machines for the production which fulfills those high quality standards. Machines sold by Arnold not only guarantee a high process stability but they are also designed and built for being integrated in a fully automatic processing line. This is a significant advantage of Arnold products.

Stella Lee is Editor of InterPV. Send your comments to pved1@infothe.com.

For more information, please send your e-mails to pved@infothe.com.

ⓒ2011 www.interpv.net All rights reserved. |